Alongside the Thermoforming Machines Type T10 and Ts1, GEISS AG also offer CNC Post Processing Centres. These can be further equipped with additional options to suit the requirements of your products, if required.

Using the parametric design, a machine of almost any size can be supplied.

The machines essentially consist of rigid, welded machine frame with a fixed table. The three main axes named as X, Y and Z relate to the perpendicular axes of a cartesian coordinate system.

The trimming spindle is held in an orthogonal or gimble head and is fitted to the machine rotationally on the vertical z axis. The pivoting b axis, the rotating c axis and the centre axis of the spindle meet at one point. During trimming the cutter tip moves continuously on a spherical surface around this cross point.

Our CNC Trimming Machine are:

• CE Certified

• Adaptable to meet the Specific Requirements of the Product in Terms of Quality, Handling, Cycle Times and much more by a Technically up to date Additional Options List

Typical options are:

• Trimming Spindles for a Variety of Application

• Additional Processing Options such as Ultrasound and Cold Knife (if no Ultrasound is required) and Laser Cutting

• Tool Changer

• Various Machine Tables such as Shuttle, Alternating and Rotary

• Machine Enclosures

• Swarf and Dust Extraction Systems

• Vacuum Equipment

• Measuring Systems

• Software Options, Data Acquisition and Logging

• Additional Services and much more

Areas of Application:

• Thermoplastics

• Glass and Carbon Fibre Reinforced Thermosets

• Moulded Parts made from GMT and SMC

• Moulded Parts made from Foam, Leather and a Carrier Part in Sandwich Form

• Wood Panelling

• Plywood Mouldings

• Lightweight Honeycomb Materials

• Blow Mouldings

• Model Making Foam for Tools and Model Making

We are happy to discuss your requirements in a person and look forward to hearing from you.

Instead of a trimming spindle, an ultrasound cutting unit with an additional NC axis can be selected from the options list. This option cuts materials without noise, materials too difficult or not suitable for spindle trimming.

The piezoelectric effect is todays mainly used in technology to generate ultrasound:

Ultrasound is used to longitudinally oscillate a cutting blade at a frequency of 20 kHz. This oscillating movement greatly reduces the cutting force (compared to Cold Knife cutting).

Applications:

Sound frequencies above the hearing limit, approximately 20 kHz, are referred to as ultrasound. Frequencies applied in Ultrasound cutting range between 20 - 40 kHz.

In todays’ technology the piezoelectric effect is main source of generating Ultrasound.

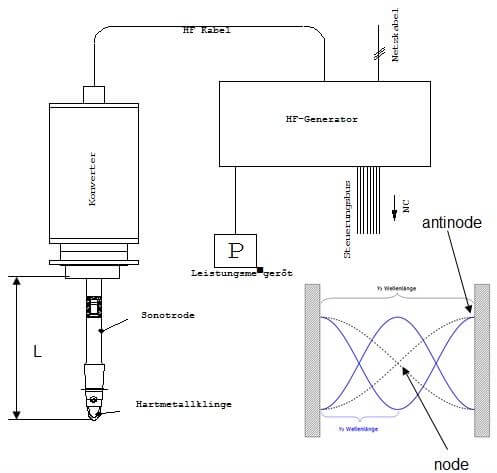

High voltage produced by a generator is applied to layered quartz crystal discs via a coaxial cable. The discs vibrate in resonance with the AC Voltage applied, resulting in mechanical vibration generating amplitudes of approximately 6-8 μm.

The unit that coverts the electrical vibration into a mechanical vibration is called a converter.

The amplitude must be increased for cutting. The transformation pieces which increase the amplitudes of the mechanical vibration to a few of a tenth millimetres are called sonotrodes.

In most cases the very precise sonotrodes are made of titanium and the cutting blade is fixed to the end of the sonotrode. The carbide knife is either clamped in a slot on the sonotrode or soldered into a screwable pin.

Alongside the Thermoforming Machines Type T10 and Ts1, GEISS AG also offer CNC Post Processing Centres. These can be further equipped with additional options to suit the requirements of your products, if required.

Using the parametric design, a machine of almost any size can be supplied.

The machines essentially consist of rigid, welded machine frame with a fixed table. The three main axes named as X, Y and Z relate to the perpendicular axes of a cartesian coordinate system.

The trimming spindle is held in an orthogonal or gimble head and is fitted to the machine rotationally on the vertical z axis. The pivoting b axis, the rotating c axis and the centre axis of the spindle meet at one point. During trimming the cutter tip moves continuously on a spherical surface around this cross point.

Our CNC Trimming Machine are:

• CE Certified

• Adaptable to meet the Specific Requirements of the Product in Terms of Quality, Handling, Cycle Times and much more by a Technically up to date Additional Options List

Typical options are:

• Trimming Spindles for a Variety of Application

• Additional Processing Options such as Ultrasound and Cold Knife (if no Ultrasound is required) and Laser Cutting

• Tool Changer

• Various Machine Tables such as Shuttle, Alternating and Rotary

• Machine Enclosures

• Swarf and Dust Extraction Systems

• Vacuum Equipment

• Measuring Systems

• Software Options, Data Acquisition and Logging

• Additional Services and much more

Areas of Application:

• Thermoplastics

• Glass and Carbon Fibre Reinforced Thermosets

• Moulded Parts made from GMT and SMC

• Moulded Parts made from Foam, Leather and a Carrier Part in Sandwich Form

• Wood Panelling

• Plywood Mouldings

• Lightweight Honeycomb Materials

• Blow Mouldings

• Model Making Foam for Tools and Model Making

We are happy to discuss your requirements in a person and look forward to hearing from you.

Instead of a trimming spindle, an ultrasound cutting unit with an additional NC axis can be selected from the options list. This option cuts materials without noise, materials too difficult or not suitable for spindle trimming.

The piezoelectric effect is todays mainly used in technology to generate ultrasound:

Ultrasound is used to longitudinally oscillate a cutting blade at a frequency of 20 kHz. This oscillating movement greatly reduces the cutting force (compared to Cold Knife cutting).

Applications:

Sound frequencies above the hearing limit, approximately 20 kHz, are referred to as ultrasound. Frequencies applied in Ultrasound cutting range between 20 - 40 kHz.

In todays’ technology the piezoelectric effect is main source of generating Ultrasound.

High voltage produced by a generator is applied to layered quartz crystal discs via a coaxial cable. The discs vibrate in resonance with the AC Voltage applied, resulting in mechanical vibration generating amplitudes of approximately 6-8 μm.

The unit that coverts the electrical vibration into a mechanical vibration is called a converter.

The amplitude must be increased for cutting. The transformation pieces which increase the amplitudes of the mechanical vibration to a few of a tenth millimetres are called sonotrodes.

In most cases the very precise sonotrodes are made of titanium and the cutting blade is fixed to the end of the sonotrode. The carbide knife is either clamped in a slot on the sonotrode or soldered into a screwable pin.

Note: All products exclude GST where applicable at the current rate.

PLASQUIP has teamed up with a highly experienced Finance Consultant, Christos Kritikos from FINLEASE, to be able to offer our highly valued customers quick and efficient access to Equipment Finance for their purchase of Capital Plant and Equipment.

Ask Christos TODAY how to secure hassle-free finance for your equipment purchase – he can be contacted on his email below:

Landline: (02) 8404 2000

Mobile: 0448 005 890

Email: CKritikos@finlease.com.au

OR you can ask for Christos in the “comments” area in the FINLEASE Contact us page.

Delivery:

It is your obligation to enter the correct delivery address details at time of ordering. If you enter the wrong address, we are not obliged to re-send the order to the correct address at our expense. It is the responsibility of you the customer to inform us if an order does not arrive in a timely manner allowing for freight carriers normal delivery time frames to your address. All orders for product that is in stock is dispatched within two working days. If an order does not arrive please inform us. Once we learn an order has not arrived within the approximate delivery time frame, we will lodge enquiries with the freight provider to search for the order. We will not be held liable for any loss or damage resulting from late delivery, but will seek compensation on your behalf, for orders which do not arrive at all.

Without limiting the operation of any other Terms and Conditions herein, you agree that late delivery by a freight provider or Plasquip Sales does not constitute a failure of our agreement and does not entitle you to cancellation of an order.

Cancellations:

If you contact us before the order is shipped, we can refund you immediately. However, if the order has already been shipped, you will have to return the consignment to us at the below address. We (Plasquip Sales) reserve the right to cancel any order for any reason whatsoever. If you have already paid for an item ordered and we choose to cancel, your money will be refunded in full.

Refunds:

If you receive a product that you believe is significantly not as described, please contact us. After discussing the issue with us we will at our discretion refund your money after the return of the product/s. It will be your responsibility to return the item/s back to our address (at your cost, unless we are at, and have acknowledged, fault) in their original condition before a refund will be issued. Any item that we intentionally sell damaged, will be clearly marked as such.

Out of Stock:

Although we keep stock quantities of most products, on some occasions we run out of some products, which on average will delay an order, if this is the case, we will inform you via email of the estimated delivery time and give you the option to proceed with the order or cancel the order and receive a full refund.

Use our finance calculator from QPF Finance and Insurance to explore flexible payment options that work for you.