Indicative Price Ex-Works Melbourne Metro

Product Description:

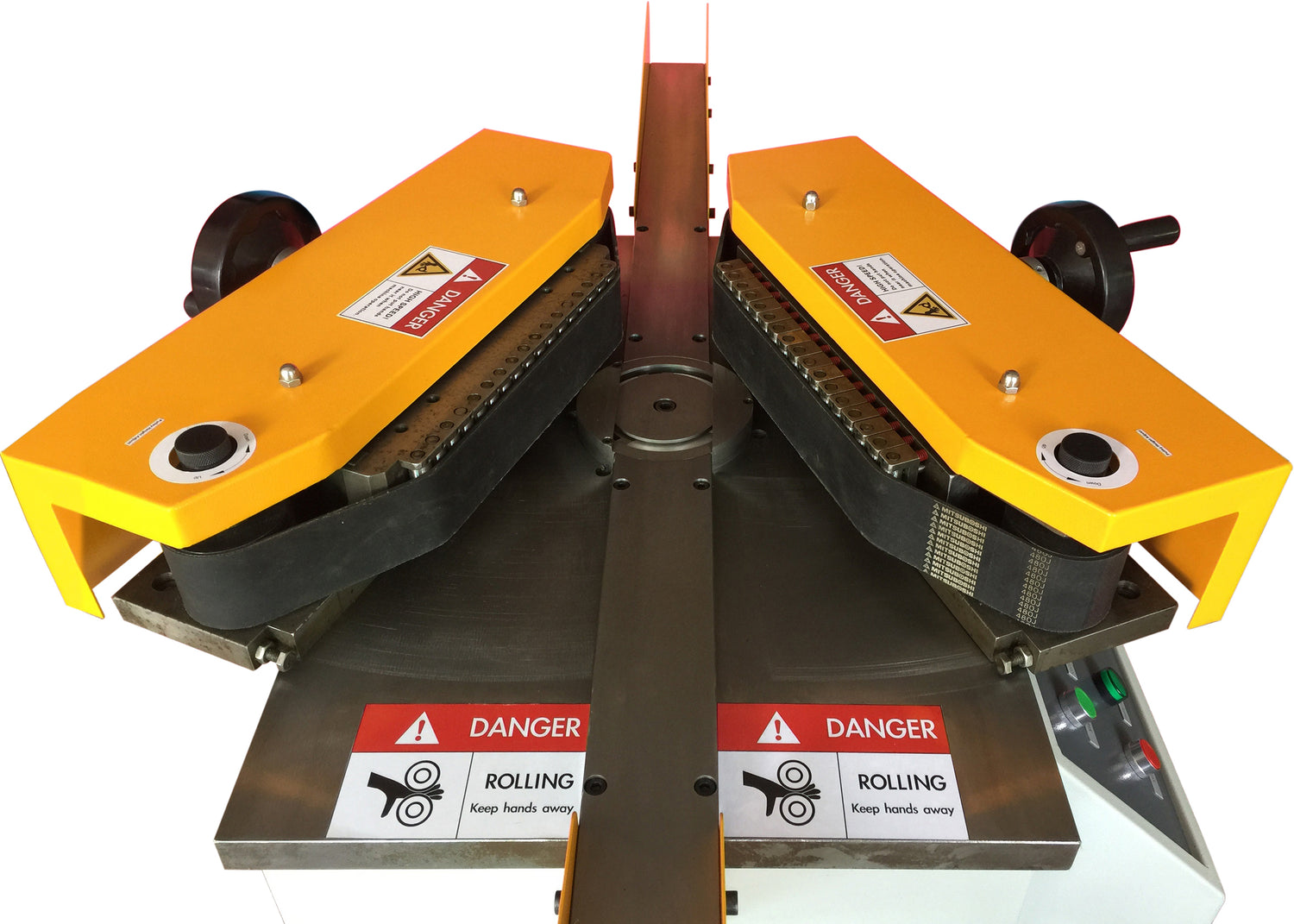

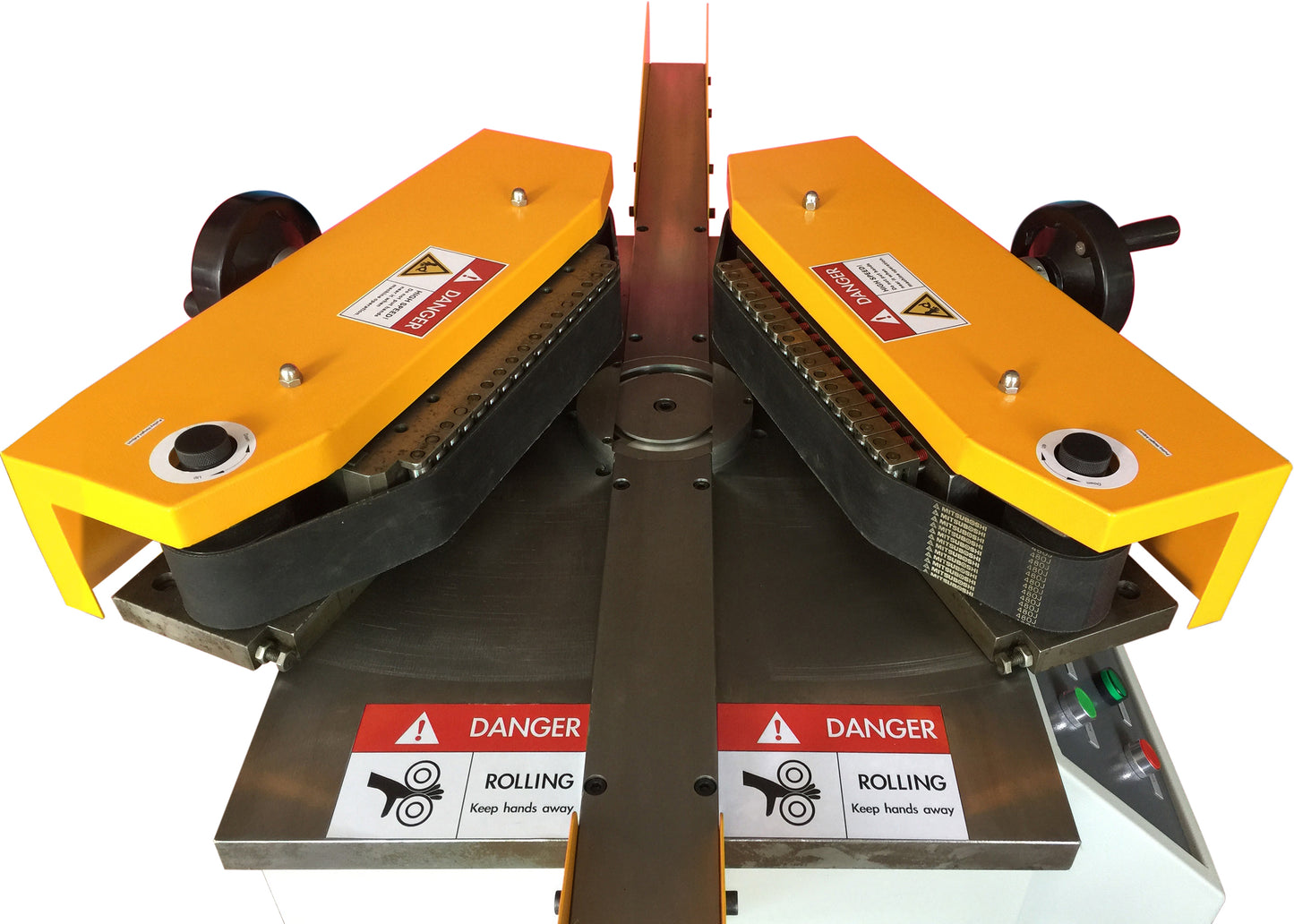

The PQ-1200 is a quality edge polishing machine offers advanced capabilities for materials polishing, boasting a maximum thickness of 80mm. Remarkably, its length capacity is unlimited.

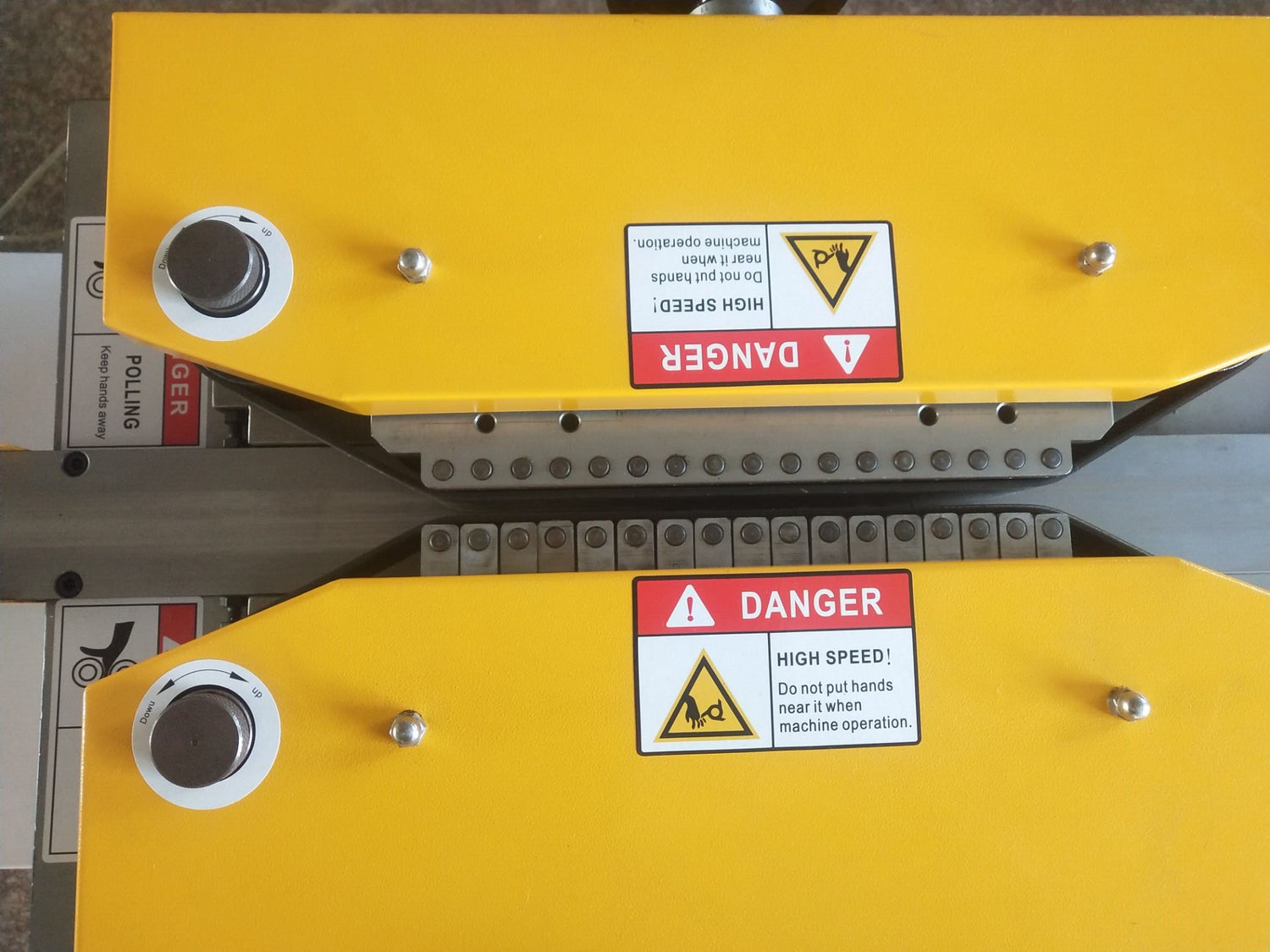

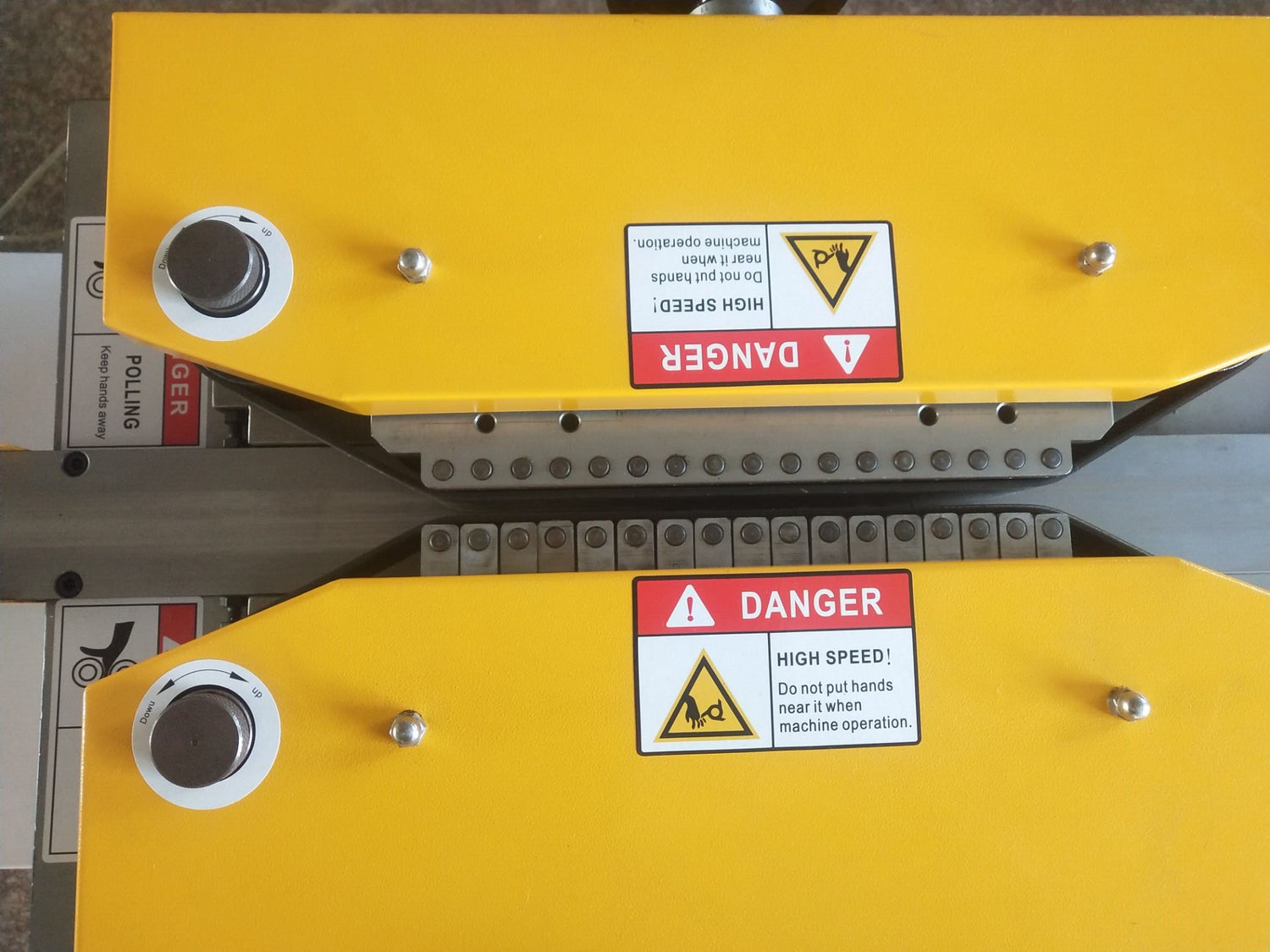

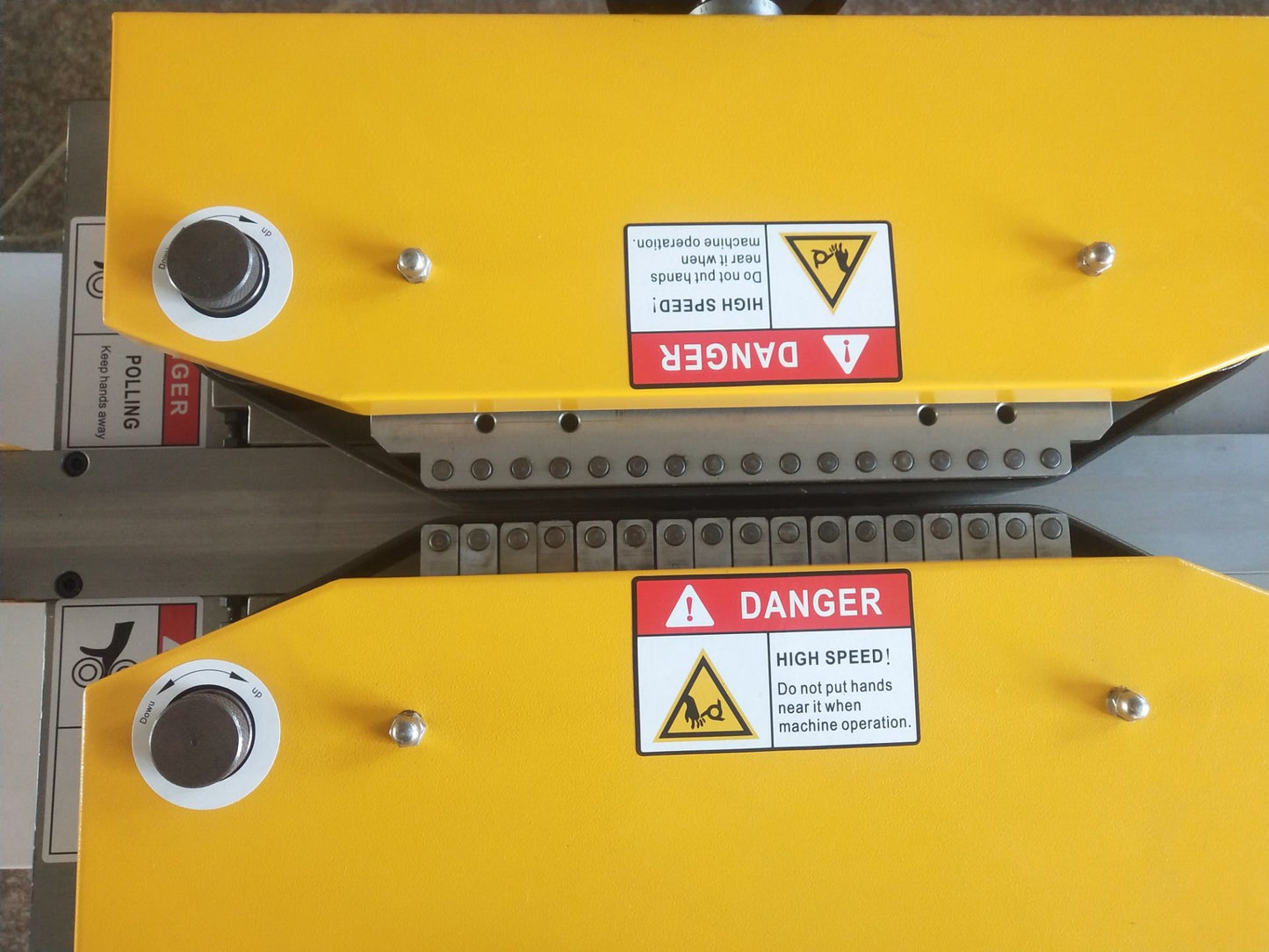

It features meticulously selected imported diamond blades that not only enhance polishing effects but also extend the product's lifespan. With two roughing blades and one finishing blade, this system guarantees both high speed and exceptional precision.

To ensure top-notch quality, the machine incorporates components from reputable sources worldwide. These include Mitsubishi belts from Japan, SKF Bearings from Switzerland, and mechanical springs from Germany.

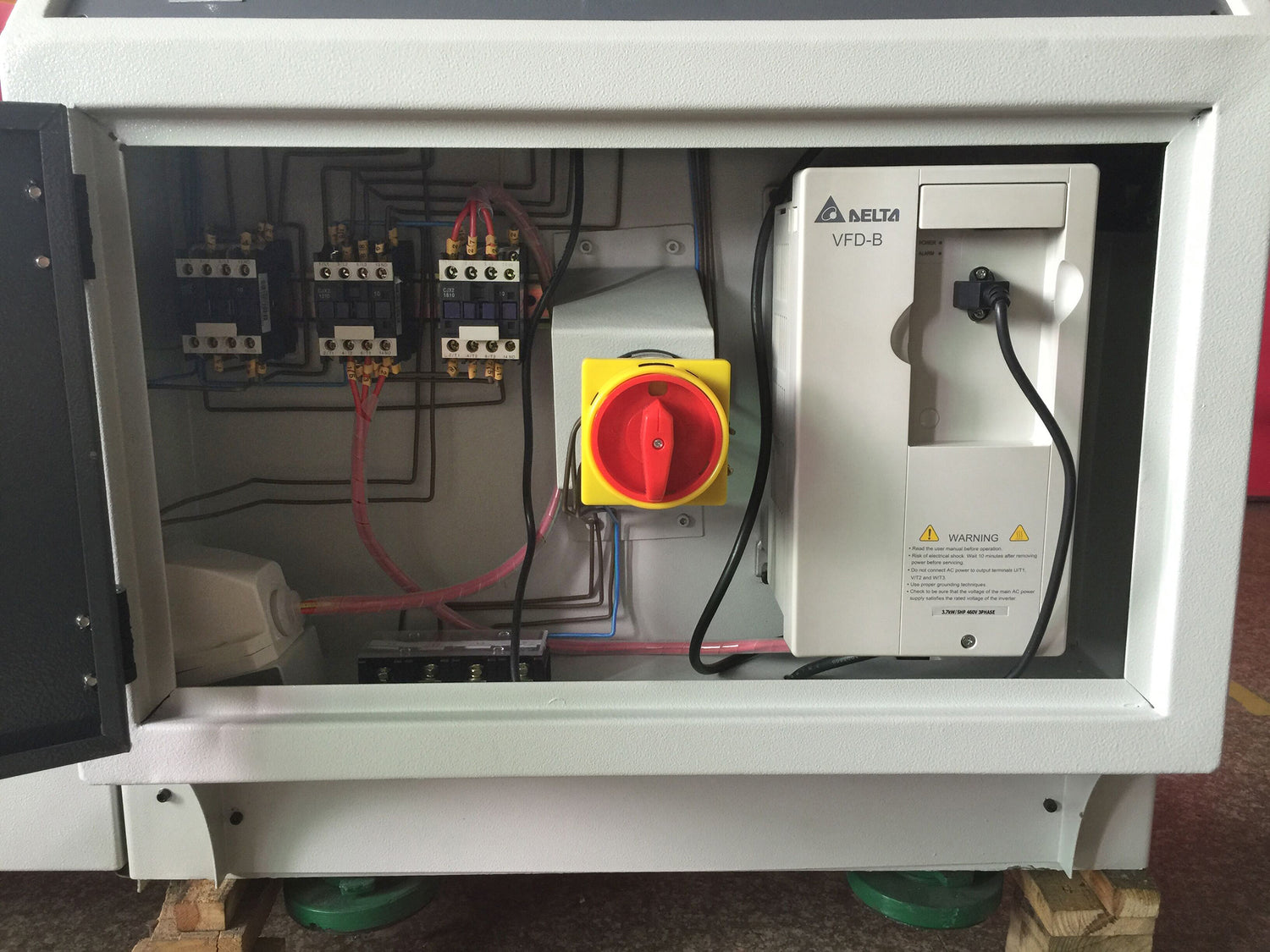

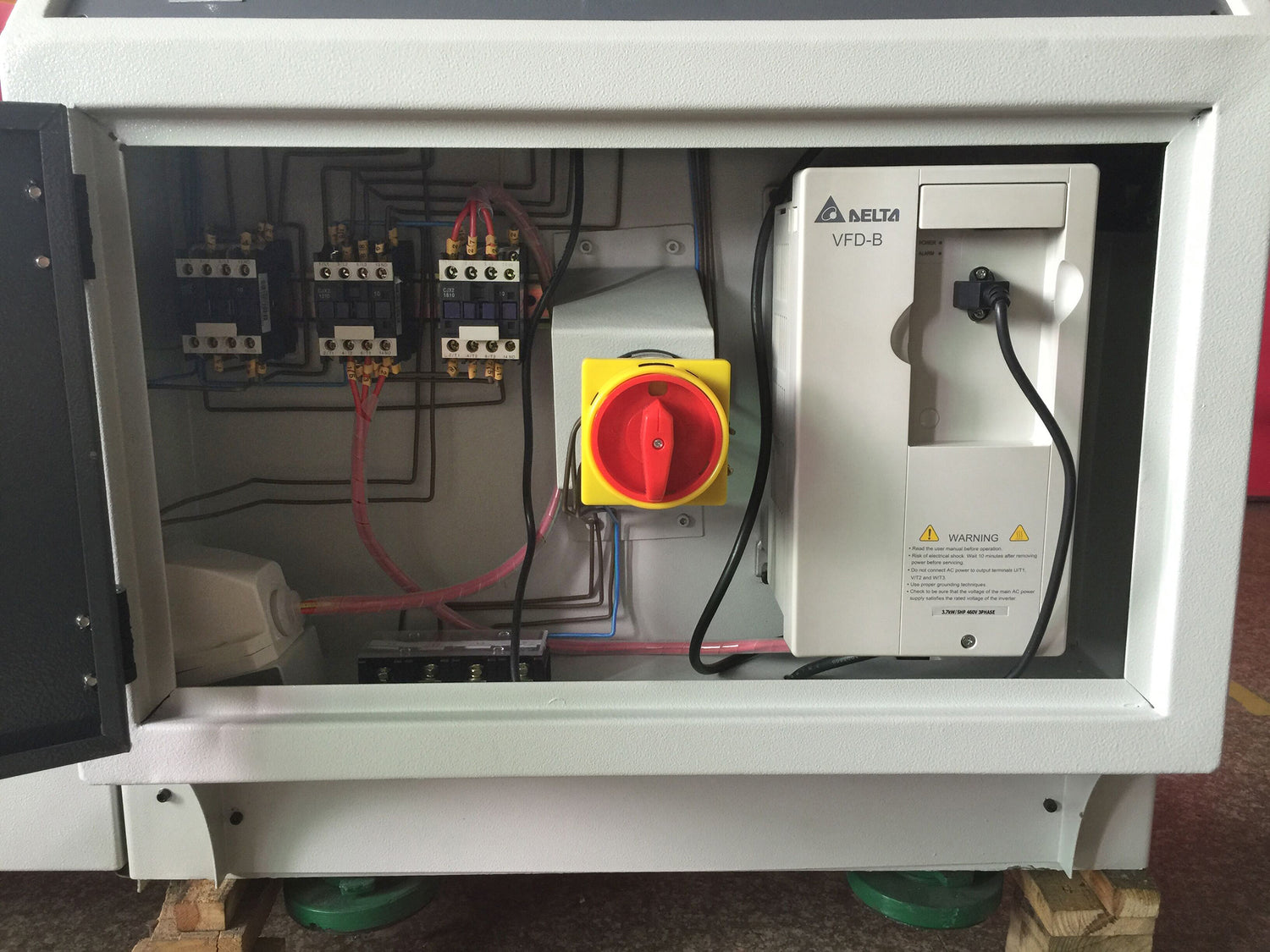

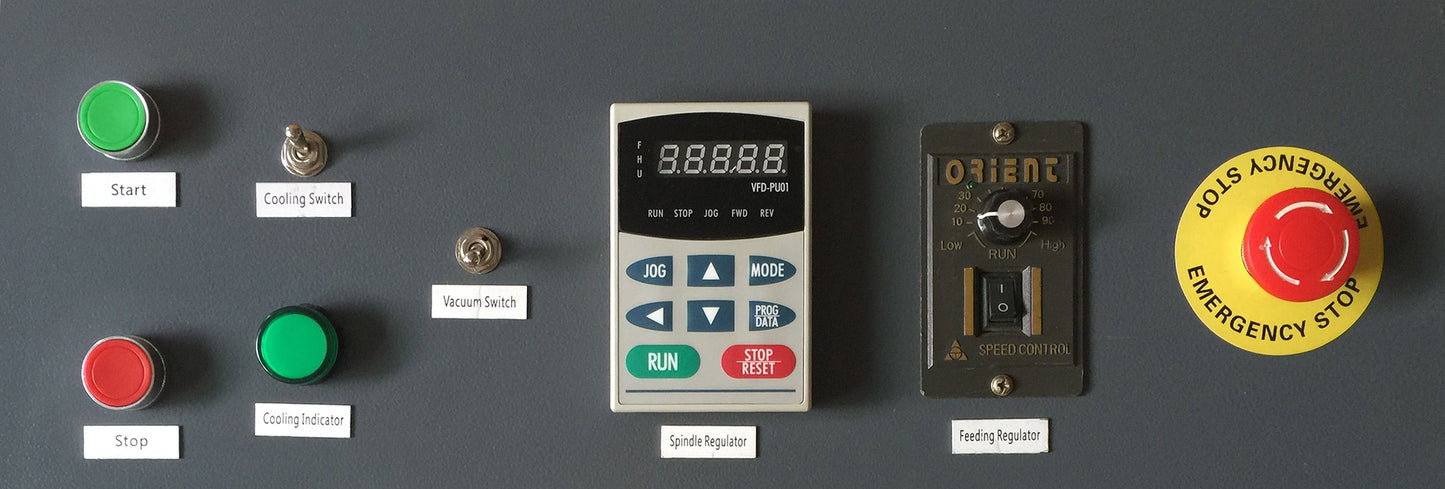

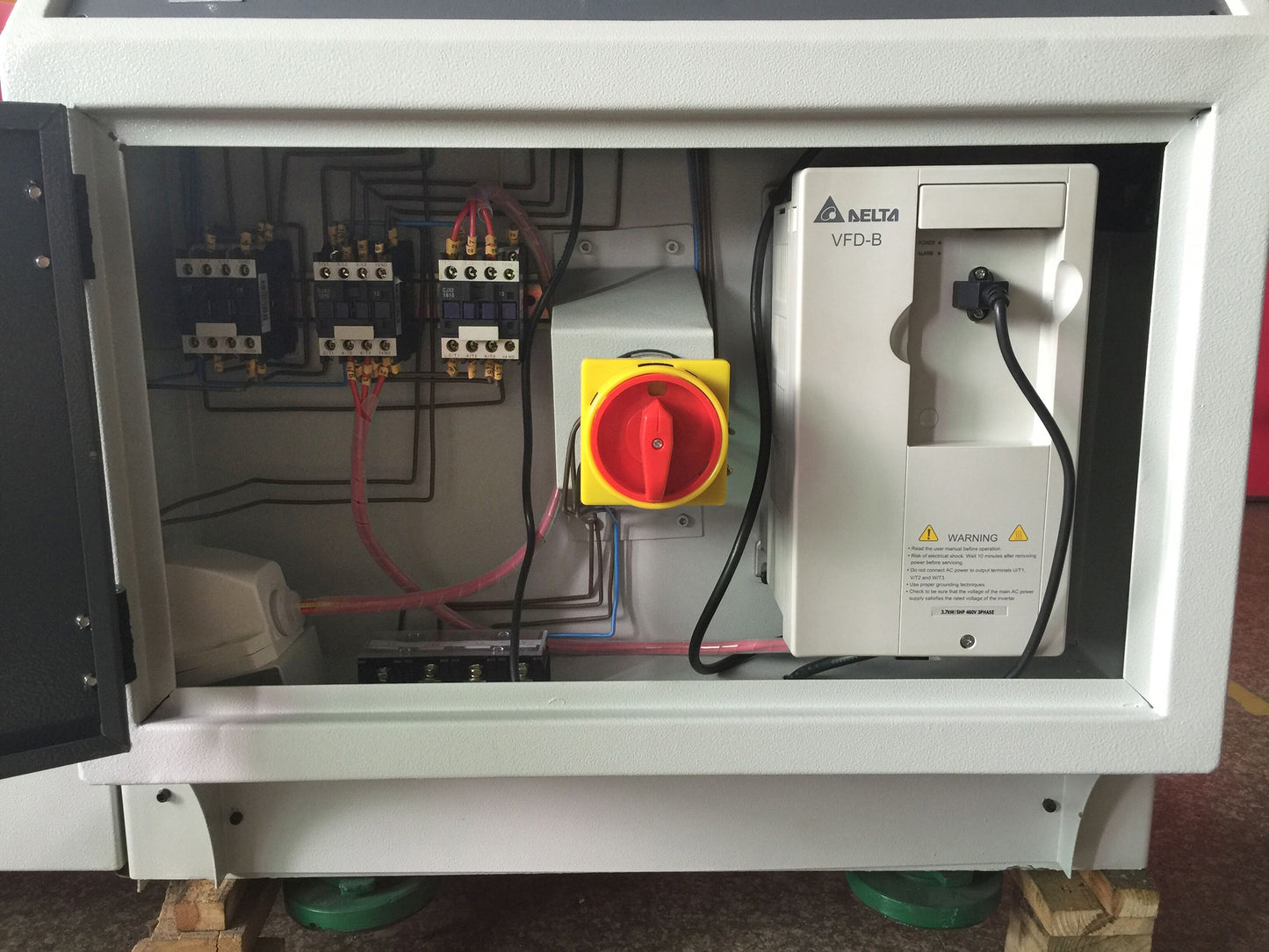

The inclusion of imported Spindle & Inverter technology guarantees a trifecta of advantages: high speed, exceptional precision, and unwavering stability.

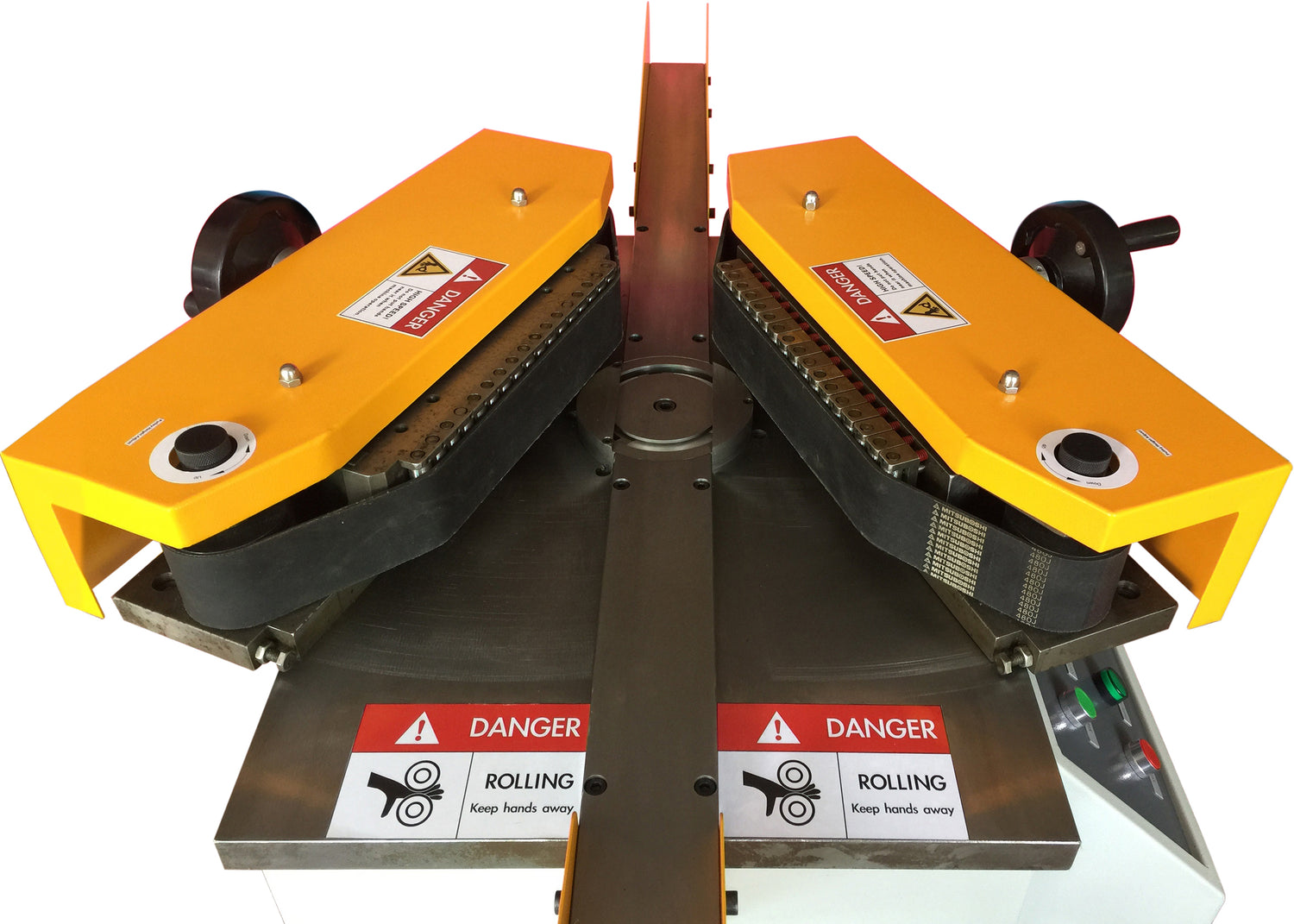

The innovative dual-motor driving and dual-belt synch-feeding mechanism obviates any concerns about staggered polishing when working with multiple sheet pieces.

The extended platform, reaching up to 1.8M, simplifies the polishing of lengthy panel sheets by enhancing feeding stability.

The platform incorporates adjustable pulleys, preventing any deviations from the parallel feeding direction with the guide rail.

The ground-breaking cutting hub design mitigates blade breakage, ensuring safety and longevity.

Automatic polishing thickness compensation facilitates seamless polishing of varying material thicknesses, with a maximum tolerance of 6mm.

The system boasts a novel vortex pump for vacuum suction, offering heightened pressure ratios, minimal noise, and energy efficiency, all while being maintenance-free.

Additionally, the integrated vacuum dust tank features an added filter net within the collector, optimizing extraction of plastic swarf from the machine.

For optimal cooling of the spindle motor, the product comes equipped with an industrial water chiller, guaranteeing superior performance.

Product Features:

Detailed parameter:

|

Model |

PQ-1200 Diamond Edge Polisher |

|

Maximum cutting length |

Unlimited |

|

Maximum Cutting width |

80(mm) |

|

Cutting mode |

End surface cutting |

|

Cutting Angle |

90 Straight line |

|

Cutting Depth |

0~0.5mm (adjustable) |

|

Cutting Speed |

>1000mm/min (Suggest 600mm/min) |

|

Spindle Speed |

6600~11000 RPM |

|

Spindle Motor |

4KW |

|

Spindle End Pulsation |

¡Ü0.01MM |

|

Work table of motion straightness error |

¡Ü0.05MM |

|

Fixed Material mode |

Manual Crank handle |

|

Diamond Tools |

2Pcs PCD blade, 1Pcs Monocrystal blade |

|

Dust Collector |

1.1 KW |

|

Dust Collector interface |

50mm |

|

Machine Dimensions |

1850x750x950 mm |

|

Input Power |

220V, Single Phrase or 380V, 3Phase |

|

Rated Power |

5.5KW (actual use 2KW) |

|

Weight |

320 KG |

|

Consumable Parts |

Blades |

Note: The specifications are updated as machines advances are made so the actual data shown.

Product Description:

The PQ-1200 is a quality edge polishing machine offers advanced capabilities for materials polishing, boasting a maximum thickness of 80mm. Remarkably, its length capacity is unlimited.

It features meticulously selected imported diamond blades that not only enhance polishing effects but also extend the product's lifespan. With two roughing blades and one finishing blade, this system guarantees both high speed and exceptional precision.

To ensure top-notch quality, the machine incorporates components from reputable sources worldwide. These include Mitsubishi belts from Japan, SKF Bearings from Switzerland, and mechanical springs from Germany.

The inclusion of imported Spindle & Inverter technology guarantees a trifecta of advantages: high speed, exceptional precision, and unwavering stability.

The innovative dual-motor driving and dual-belt synch-feeding mechanism obviates any concerns about staggered polishing when working with multiple sheet pieces.

The extended platform, reaching up to 1.8M, simplifies the polishing of lengthy panel sheets by enhancing feeding stability.

The platform incorporates adjustable pulleys, preventing any deviations from the parallel feeding direction with the guide rail.

The ground-breaking cutting hub design mitigates blade breakage, ensuring safety and longevity.

Automatic polishing thickness compensation facilitates seamless polishing of varying material thicknesses, with a maximum tolerance of 6mm.

The system boasts a novel vortex pump for vacuum suction, offering heightened pressure ratios, minimal noise, and energy efficiency, all while being maintenance-free.

Additionally, the integrated vacuum dust tank features an added filter net within the collector, optimizing extraction of plastic swarf from the machine.

For optimal cooling of the spindle motor, the product comes equipped with an industrial water chiller, guaranteeing superior performance.

Product Features:

Detailed parameter:

|

Model |

PQ-1200 Diamond Edge Polisher |

|

Maximum cutting length |

Unlimited |

|

Maximum Cutting width |

80(mm) |

|

Cutting mode |

End surface cutting |

|

Cutting Angle |

90 Straight line |

|

Cutting Depth |

0~0.5mm (adjustable) |

|

Cutting Speed |

>1000mm/min (Suggest 600mm/min) |

|

Spindle Speed |

6600~11000 RPM |

|

Spindle Motor |

4KW |

|

Spindle End Pulsation |

¡Ü0.01MM |

|

Work table of motion straightness error |

¡Ü0.05MM |

|

Fixed Material mode |

Manual Crank handle |

|

Diamond Tools |

2Pcs PCD blade, 1Pcs Monocrystal blade |

|

Dust Collector |

1.1 KW |

|

Dust Collector interface |

50mm |

|

Machine Dimensions |

1850x750x950 mm |

|

Input Power |

220V, Single Phrase or 380V, 3Phase |

|

Rated Power |

5.5KW (actual use 2KW) |

|

Weight |

320 KG |

|

Consumable Parts |

Blades |

Note: The specifications are updated as machines advances are made so the actual data shown.

Note: All products exclude GST where applicable at the current rate.

PLASQUIP has teamed up with a highly experienced Finance Consultant, Christos Kritikos from FINLEASE, to be able to offer our highly valued customers quick and efficient access to Equipment Finance for their purchase of Capital Plant and Equipment.

Ask Christos TODAY how to secure hassle-free finance for your equipment purchase – he can be contacted on his email below:

Landline: (02) 8404 2000

Mobile: 0448 005 890

Email: CKritikos@finlease.com.au

OR you can ask for Christos in the “comments” area in the FINLEASE Contact us page.

Delivery:

It is your obligation to enter the correct delivery address details at time of ordering. If you enter the wrong address, we are not obliged to re-send the order to the correct address at our expense. It is the responsibility of you the customer to inform us if an order does not arrive in a timely manner allowing for freight carriers normal delivery time frames to your address. All orders for product that is in stock is dispatched within two working days. If an order does not arrive please inform us. Once we learn an order has not arrived within the approximate delivery time frame, we will lodge enquiries with the freight provider to search for the order. We will not be held liable for any loss or damage resulting from late delivery, but will seek compensation on your behalf, for orders which do not arrive at all.

Without limiting the operation of any other Terms and Conditions herein, you agree that late delivery by a freight provider or Plasquip Sales does not constitute a failure of our agreement and does not entitle you to cancellation of an order.

Cancellations:

If you contact us before the order is shipped, we can refund you immediately. However, if the order has already been shipped, you will have to return the consignment to us at the below address. We (Plasquip Sales) reserve the right to cancel any order for any reason whatsoever. If you have already paid for an item ordered and we choose to cancel, your money will be refunded in full.

Refunds:

If you receive a product that you believe is significantly not as described, please contact us. After discussing the issue with us we will at our discretion refund your money after the return of the product/s. It will be your responsibility to return the item/s back to our address (at your cost, unless we are at, and have acknowledged, fault) in their original condition before a refund will be issued. Any item that we intentionally sell damaged, will be clearly marked as such.

Out of Stock:

Although we keep stock quantities of most products, on some occasions we run out of some products, which on average will delay an order, if this is the case, we will inform you via email of the estimated delivery time and give you the option to proceed with the order or cancel the order and receive a full refund.

Use our finance calculator from QPF Finance and Insurance to explore flexible payment options that work for you.