Indicative Price Ex-Works Melbourne Metro

****New to the Australian Market****Especially made to our own Specification ****

150W, 300W, 500W and 620W ALSO AVAILABLE.

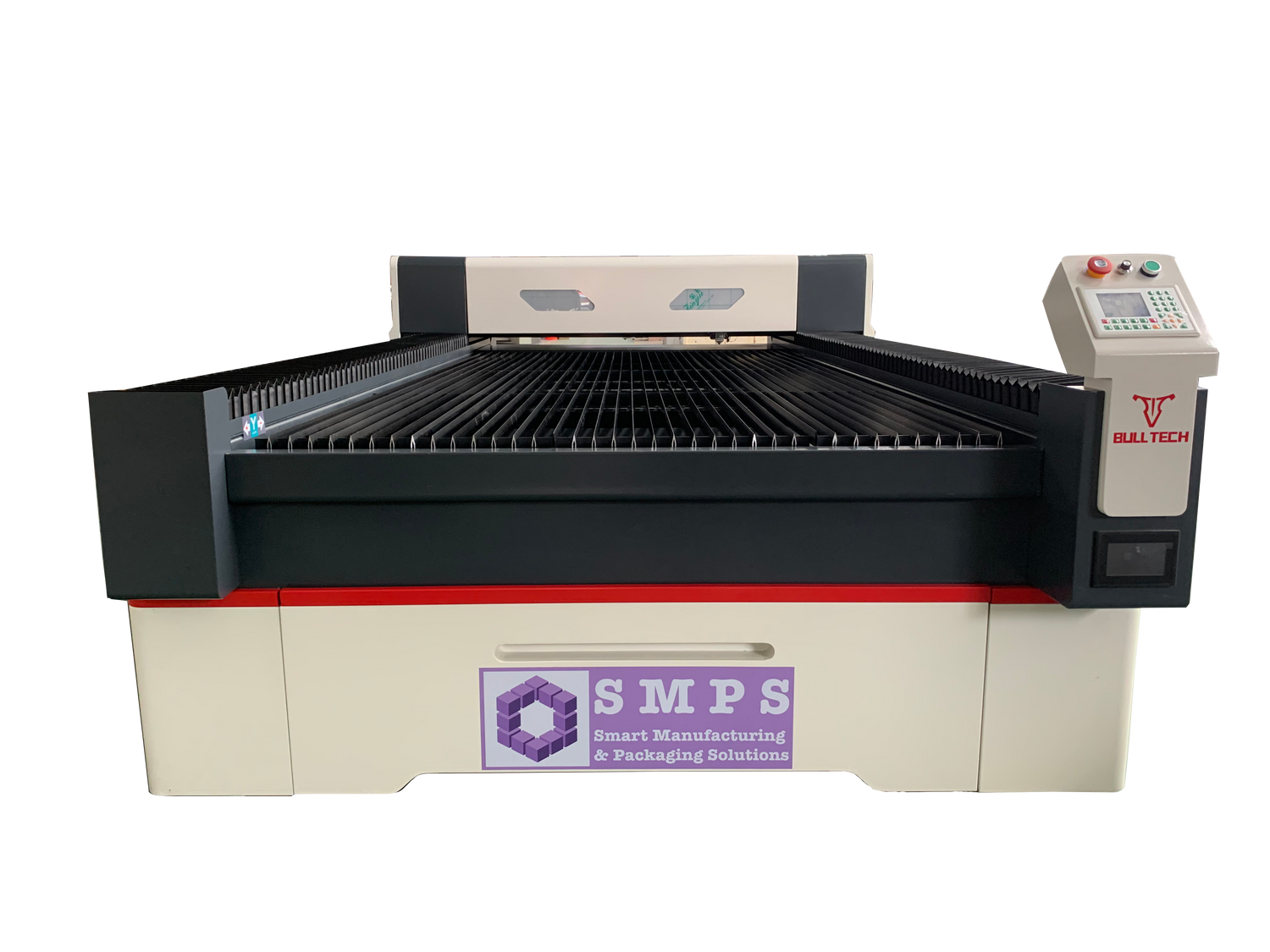

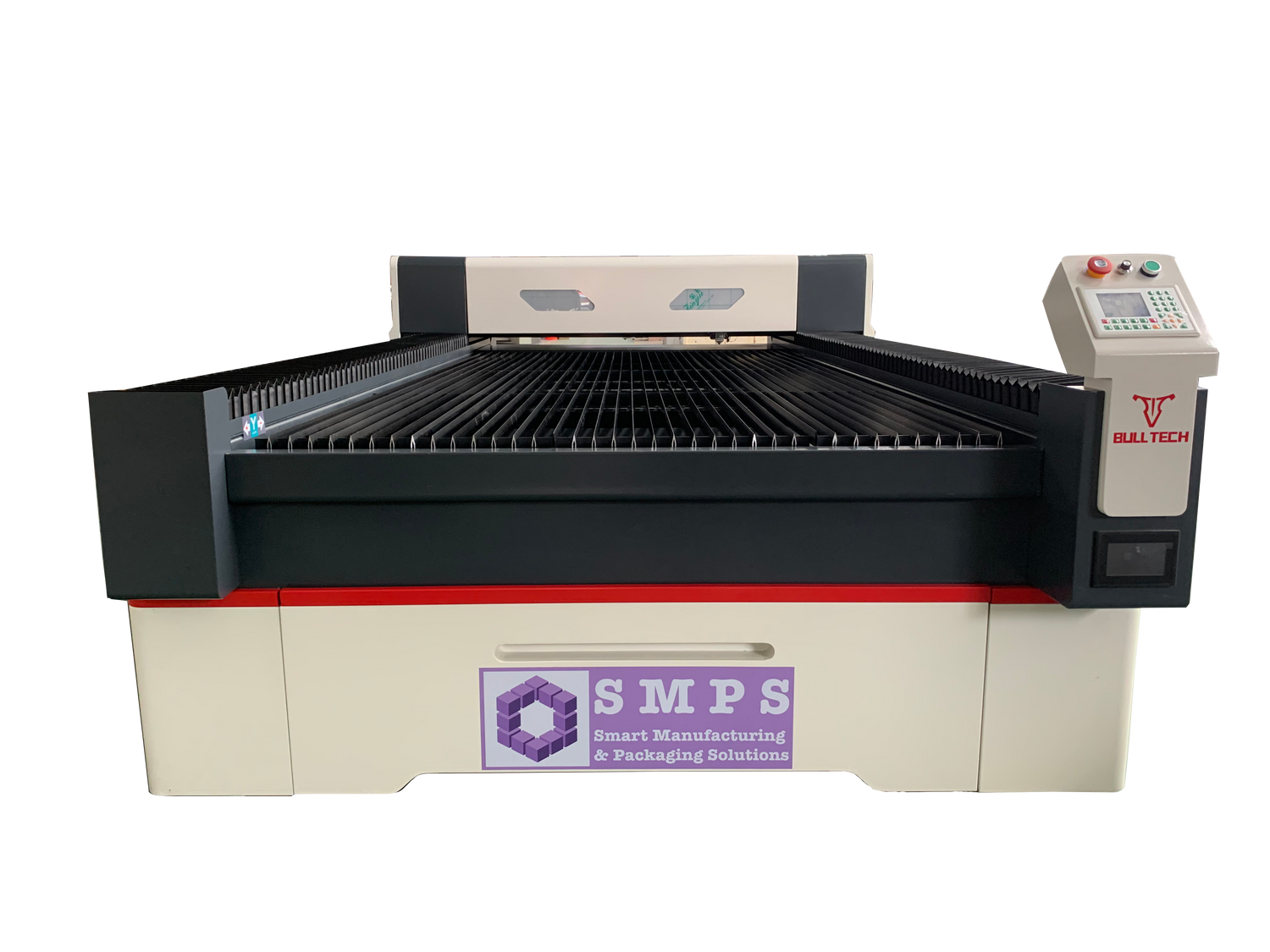

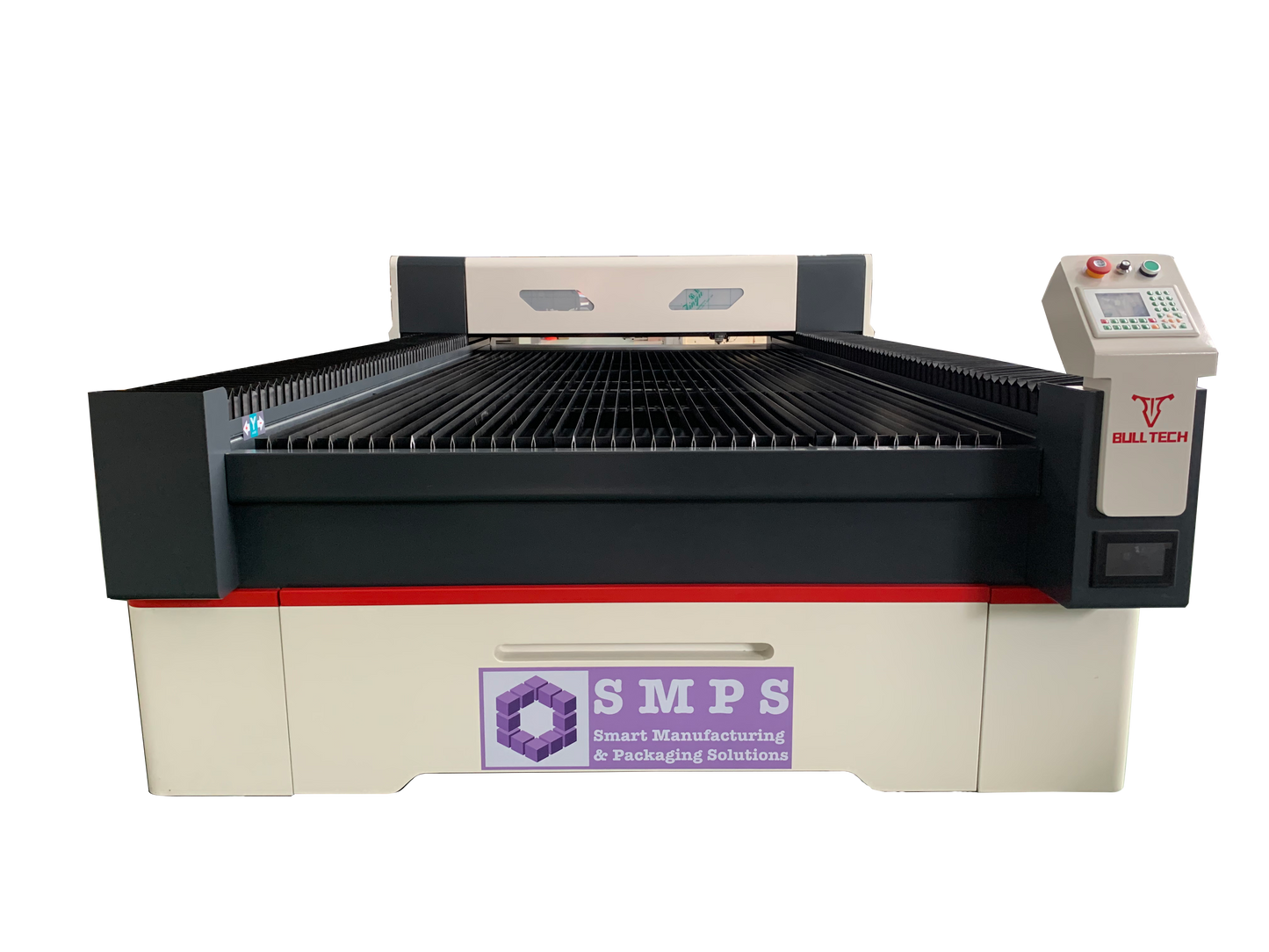

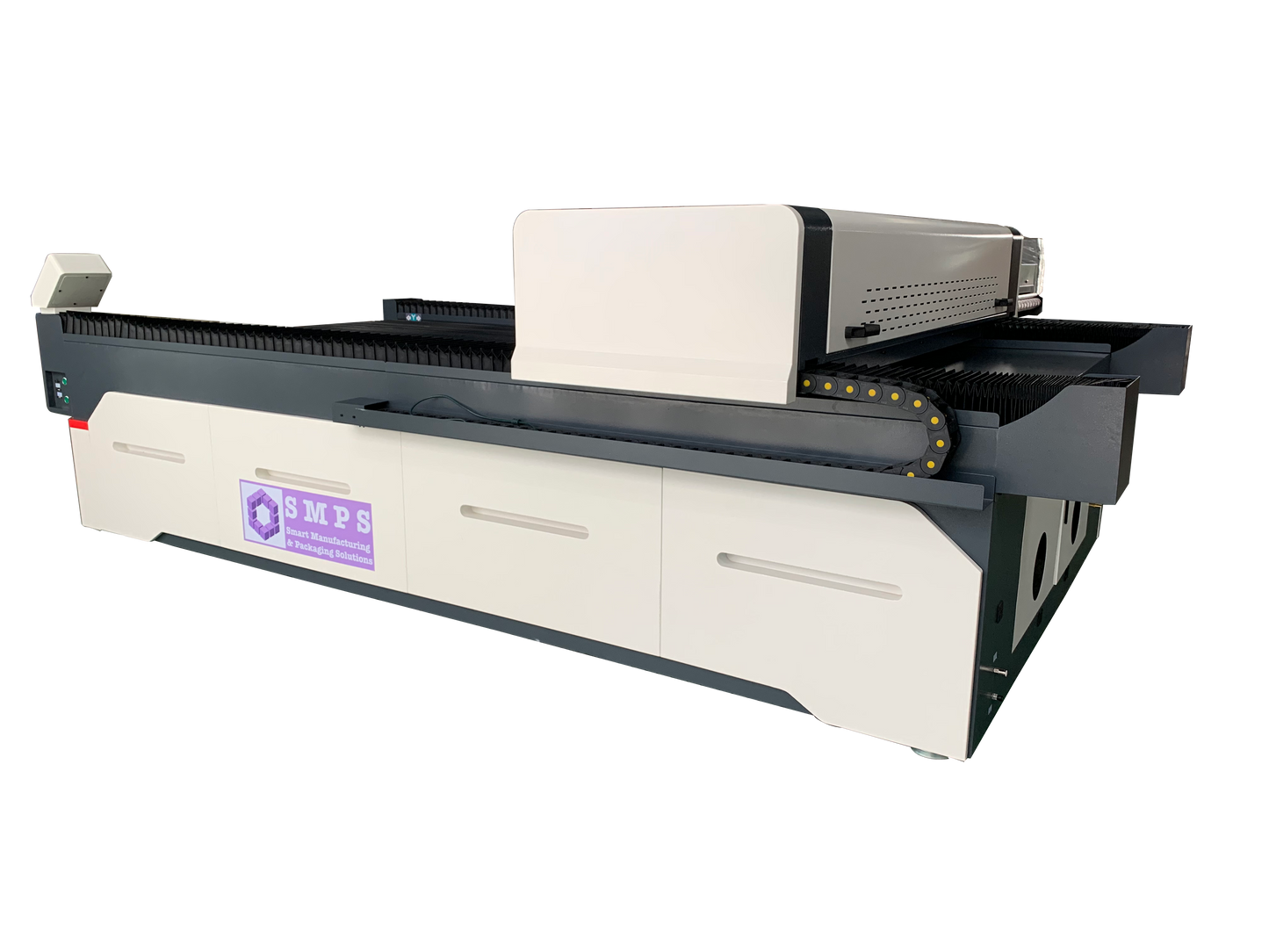

The AXIS Bulltech RP2513 laser cutting and engraving machine range with it 2500mm x 1300mm bed has been designed by Smart Manufacturing & Packaging Solutions in conjunction with Bulltech to suit even the toughest of user and can handle larger format material to give you even more versatility and higher production rates.

It does not matter if your cutting thin or thick non metal materials there is a machine that just perfect for you. Ranging in power from 150W to 620W and Belt or precision Rack and Pinon drive system we have a machine to fit your budget and your needs.

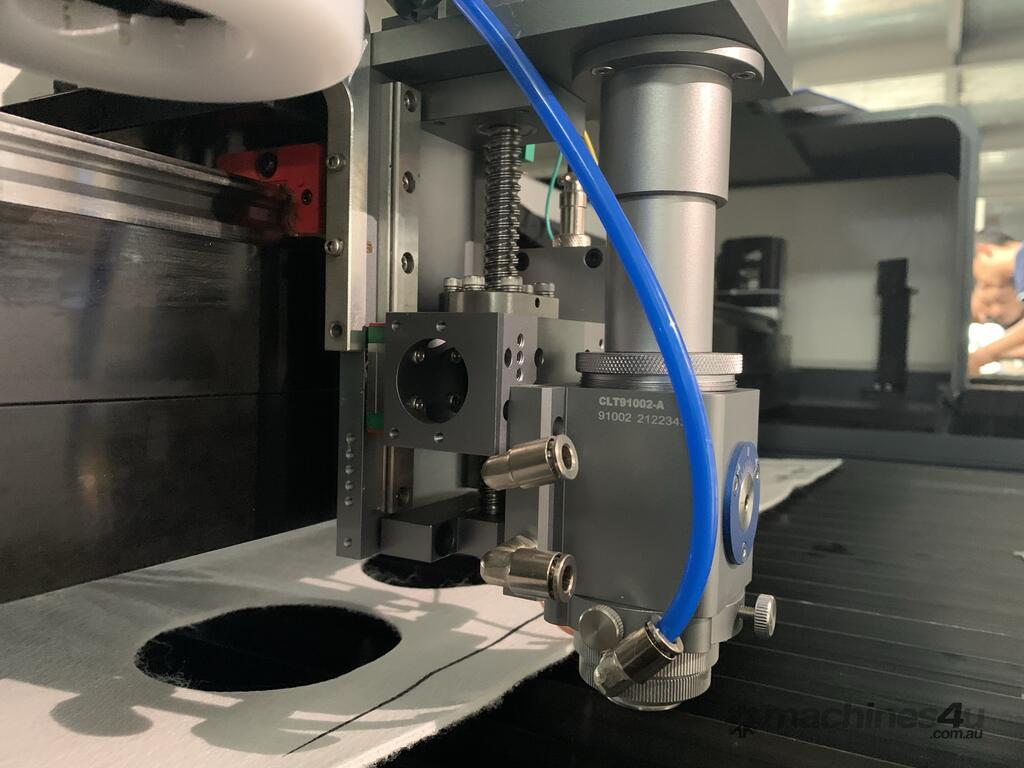

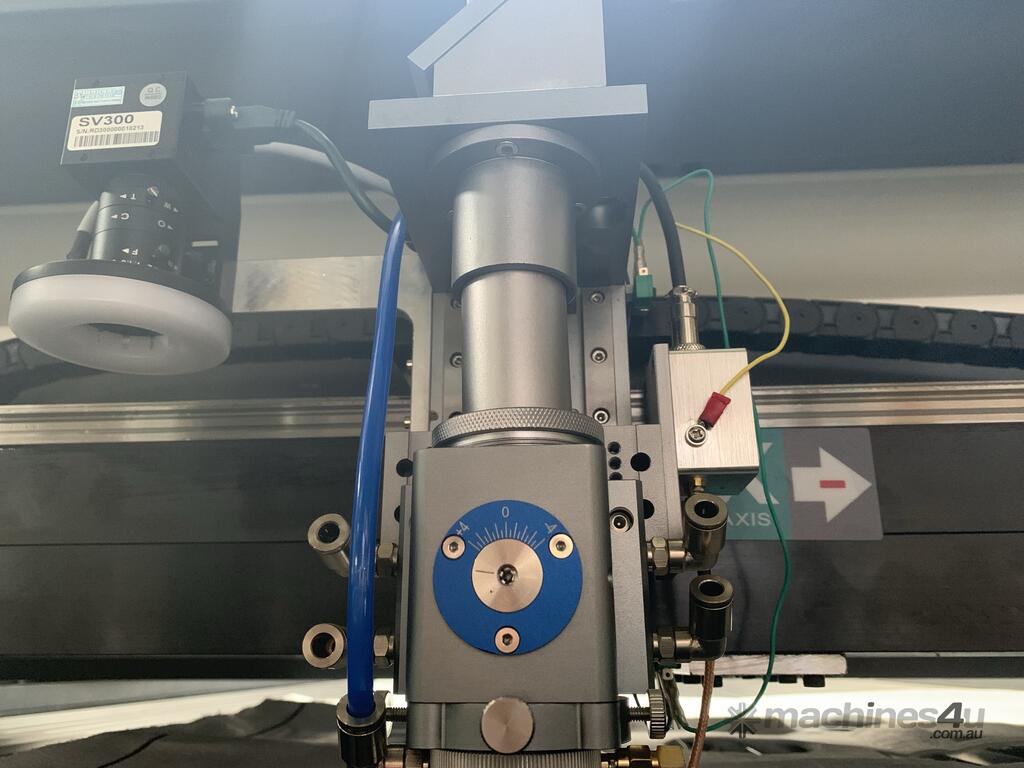

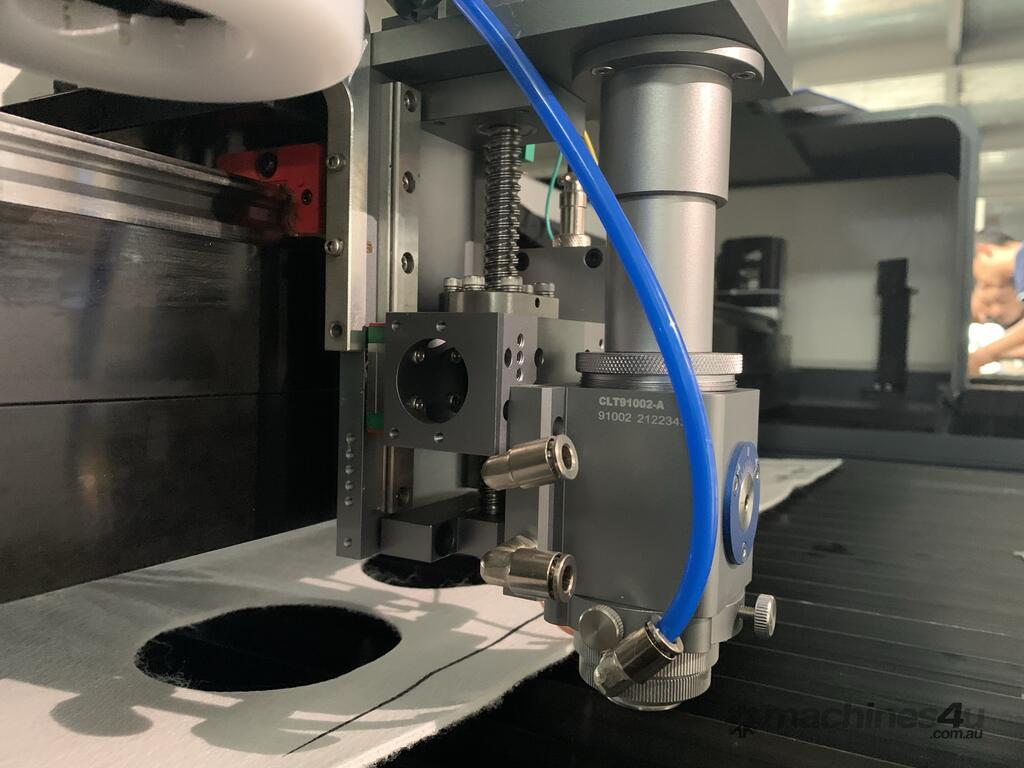

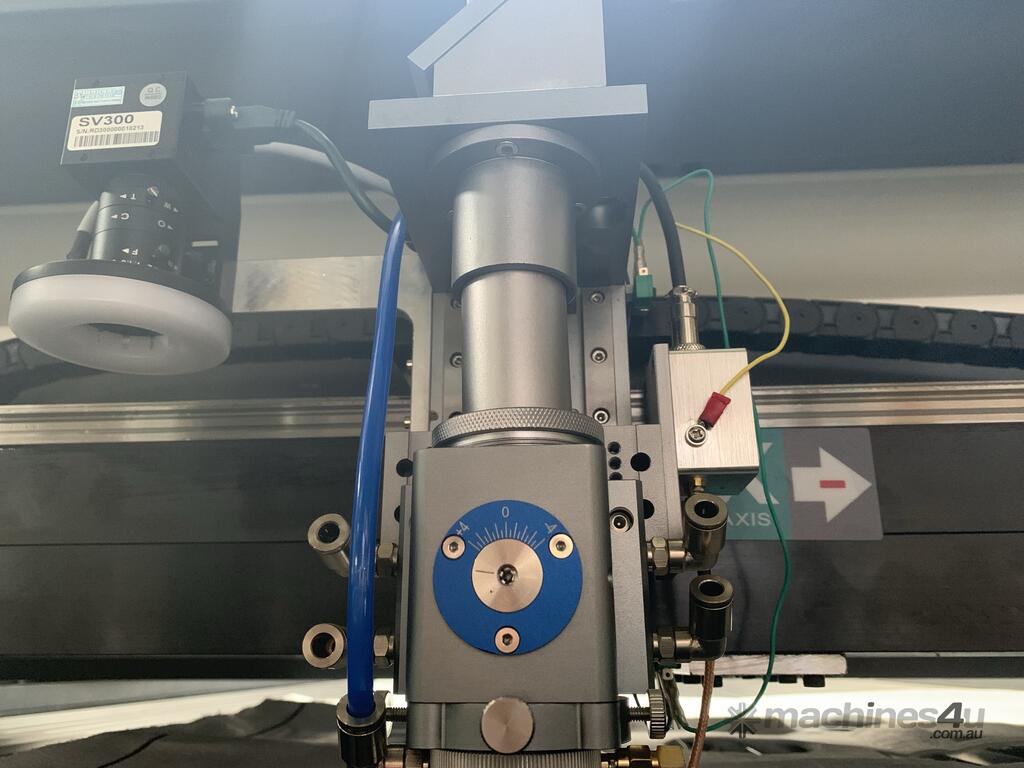

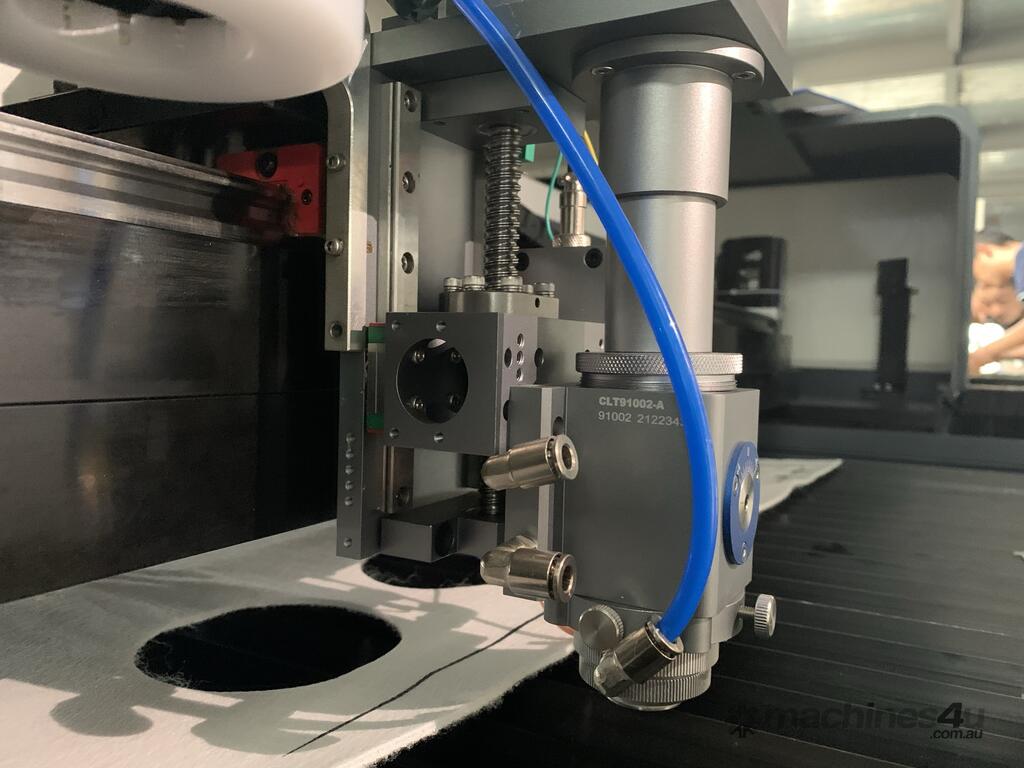

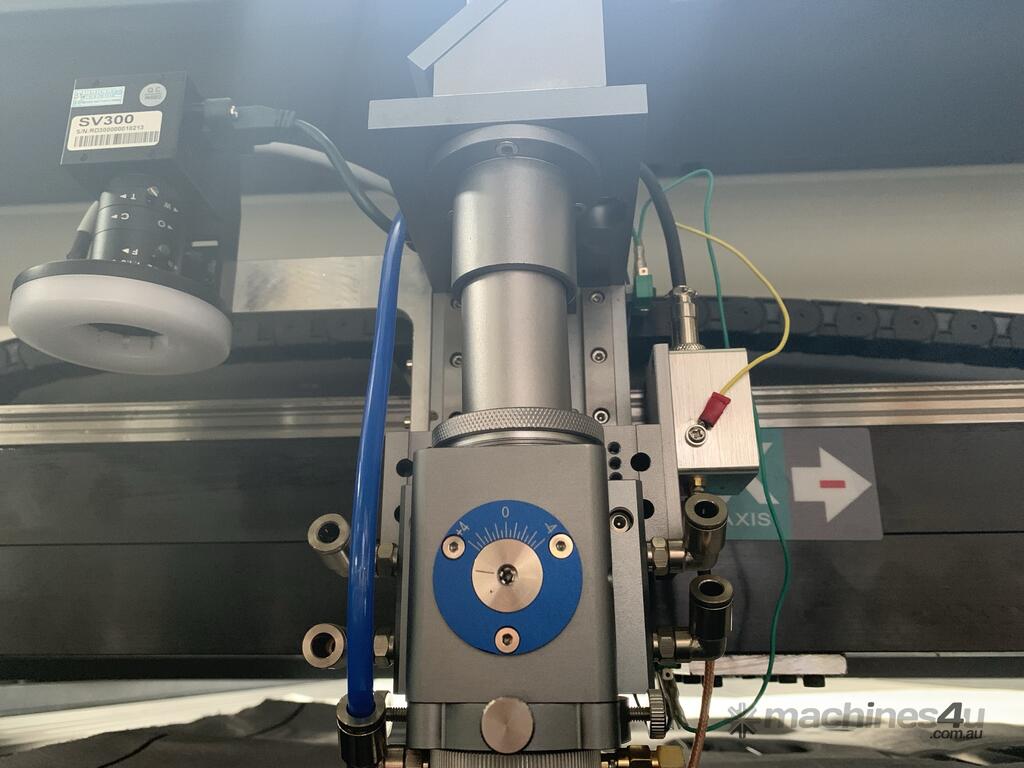

If you need to cut thin Stainless or Mild Steel then the combination of the optional Hybrid Cutting Head with Oxygen assist we can do that too. Our hybrid laser head with oxygen assist and RuiDa autofocus system makes cutting thin metal easy. The RuiDa autofocus system ensures that the Hydrid cutting head tracks the metal surface accurately over warps or bends, providing consistent cutting and gas pressure.

The 150W machine allows you to cut up to 18mm acrylic and 20mm mdf/ply in one pass and up to 1.5mm mild steel and 1mm stainless steel. The 300W and above allows you to cut up to 30mm acrylic and 25mm mdf/ply in one pass and up to 2.5mm mild steel and 2mm stainless steel. With the 300W you'll also be able to cut standard thinner materials (e.g. 3mm acrylic) at up to twice the speed of a standard 150W machine, reducing production time by up to 50%! The 500W and 620W versions are even faster.

If you need a camera system to cut preprinted material well we have got you covered. Each machine has our CCD 3 point camera system as an affordable optional extra.

The large bed size and the open design of the machine allows for easy loading of full size sheet for cutting. Our latest machine with ball rollers at the front of the machine provides a rolling surface for loading and un-loading sheets. Sheets can be loaded easily without scratching or damaging materials.

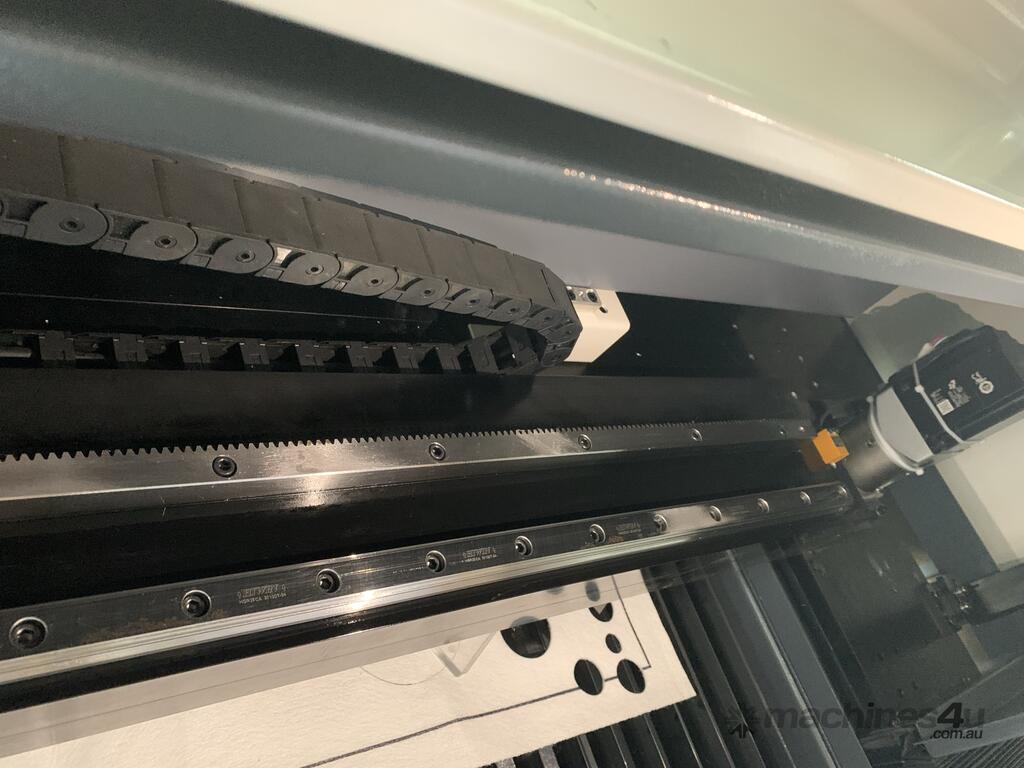

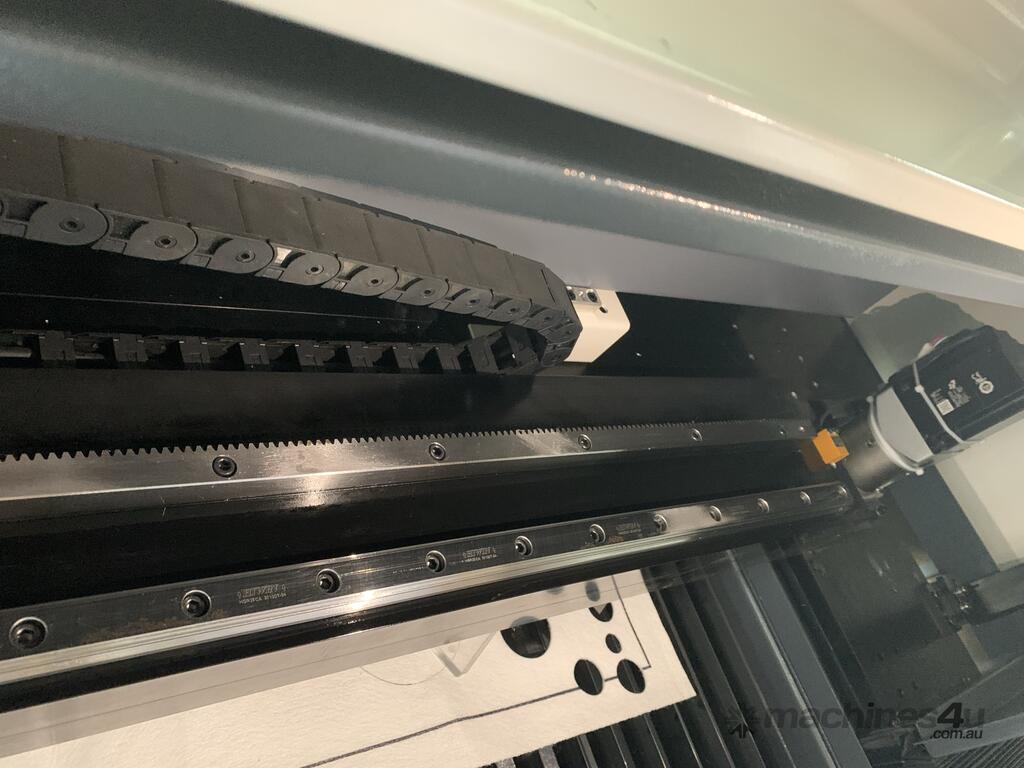

The precision Rack and Pinion drive provides higher accuracy for cutting and engraving when compared to standard belt drive and ball and screw systems. The higher acceleration and deceleration that this machine offers is particularly important for the super high speeds that the more powerful machines move at and also for metal cutting because it ensures consistency of cutting depth and smoother travel for a cleaner edge.

A top of the range S&A water chiller is included with all the machines. Extraction fan and small air pump are also included.

We supply SLW C02 Glass Laser tube system all our machines. We believe these are the best systems in the market and these tubes just like the machine is backed with a 12 month warranty. Most if not all our competitors offer 6 to 10 month warranty on their tubes. So if they don't trust the quality of their laser tubes, should you!!! You should also keep in mind that tubes 300W and above have a reasonably high replacement cost. Therefore the best quality SLW tubes will pay for themselves.

Our Rack and Pinion machines are also fitted with an automatic oiling system. You won't find this system on cheaper equipment and most of our more expensive competitors don't offer this solution either.

MACHINE FEATURES

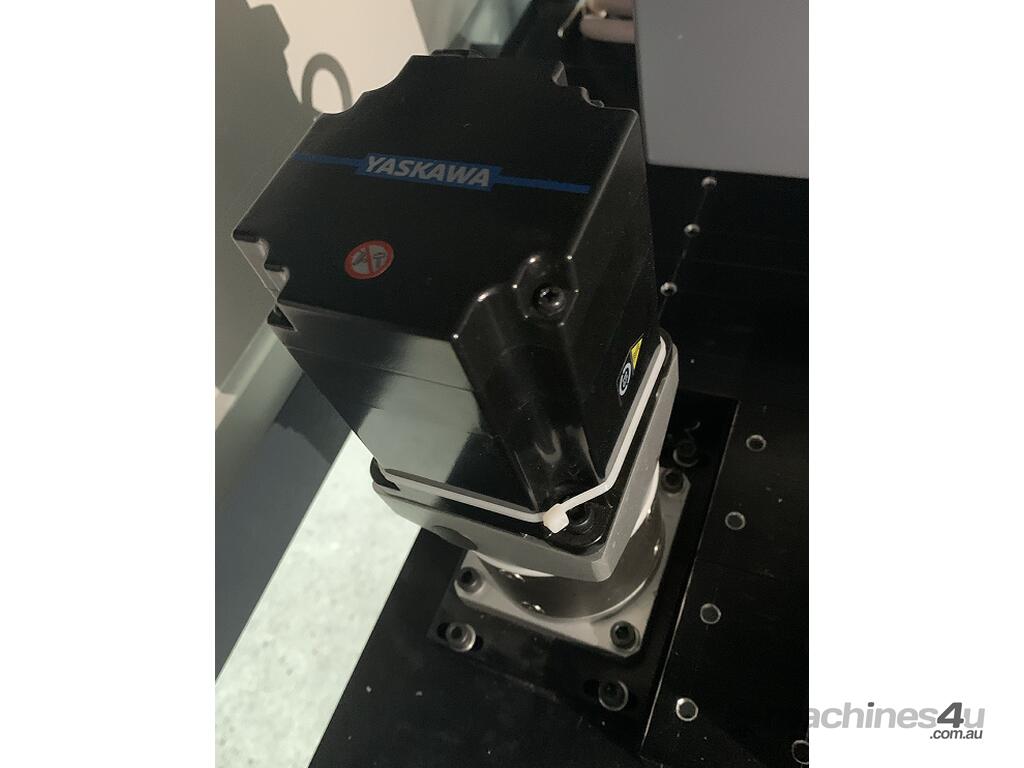

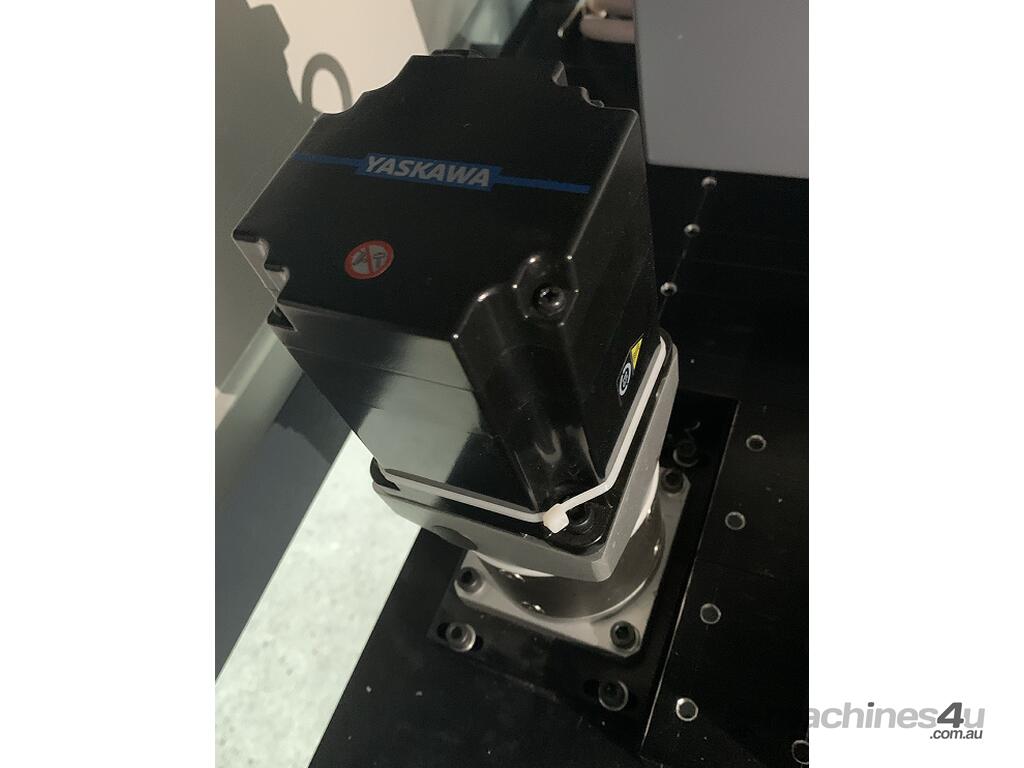

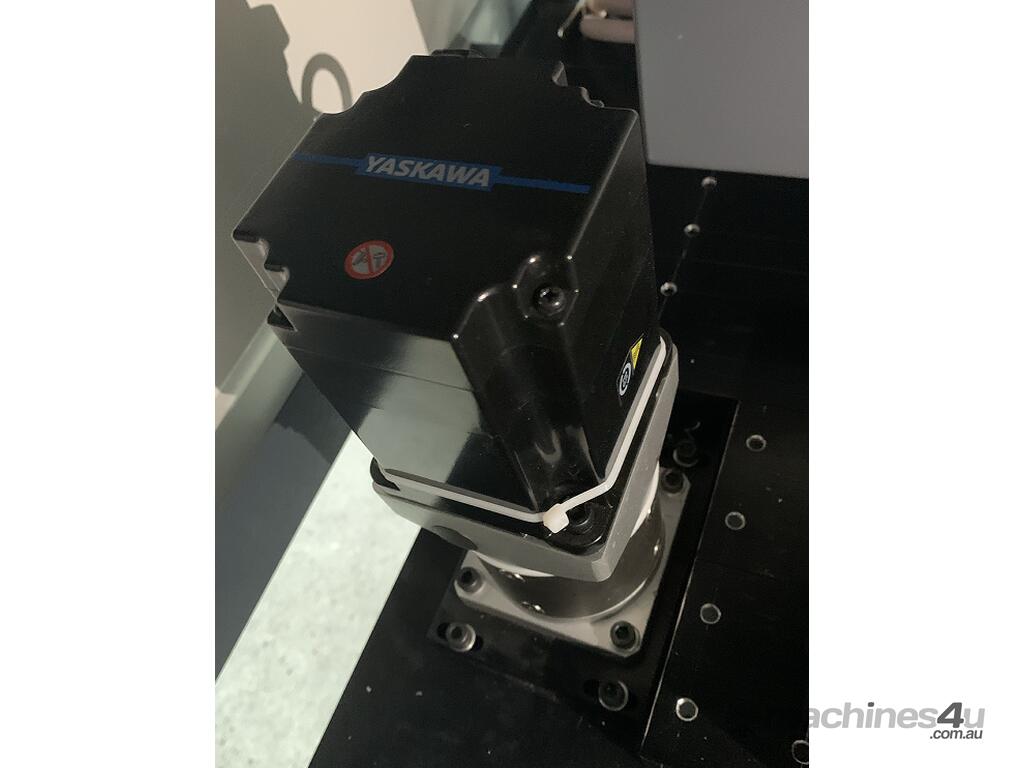

Using high-speed laser optics which achieve high cutting speeds with minimal laser optic loss * II-V Focus Lens * Precision YASKAWA servo motor system MADE IN JAPAN * Aluminium Strip-Knife Table * large Chiller Unit for constant operating temperatures * CCD or overhead gantree camera system for cutting pre-printed product * Red Light Pointer * Special Laser Head/ Auto focus * High Speed/High-Precision Rack & Pinion Drive System which can achieve high transmission accuracy, up to 0.1mm, infinite length continuation and high transmission speeds, larger than 2m/s and maximum acceleration of 10,000mm/s with excellent precision and repeatability that ensures high quality cutting and smooth operation. With X- axis synchronous feeding for 24/7 operation and a service life of more than 10 years, the AXIS Bulltech RP2513-series Flat Bed machines represents stability and performance at an affordable price.

All this matched with the RD WORKS or Lightburn Software (other option available) laser cutting and engraving software gives you a powerful yet easy to use design and operating system. The RD WORKS and Lightburn software supports .PLT * .DST * .AI * GLD * .DXF * DWG formats. RDworks is compatible with PC and Lightburn is compatible with both PC and MAC OS computers. The Lightburn software package features easy, intuitive functionality. Click here to trial the Lightburn software

As an option we can supply you with fume extraction systems which are highly recommend for home, office and in fact anywhere where the smell of the laser cutting may be a problem.

Machines fitted with 300W laser tubes and above are not suitable for engraving.

SMPS Bulltech RP2513 from Peter Shephard on Vimeo.

Bulltech RP2513-300W - SD 480p from Peter Shephard on Vimeo.

****New to the Australian Market****Especially made to our own Specification ****

150W, 300W, 500W and 620W ALSO AVAILABLE.

The AXIS Bulltech RP2513 laser cutting and engraving machine range with it 2500mm x 1300mm bed has been designed by Smart Manufacturing & Packaging Solutions in conjunction with Bulltech to suit even the toughest of user and can handle larger format material to give you even more versatility and higher production rates.

It does not matter if your cutting thin or thick non metal materials there is a machine that just perfect for you. Ranging in power from 150W to 620W and Belt or precision Rack and Pinon drive system we have a machine to fit your budget and your needs.

If you need to cut thin Stainless or Mild Steel then the combination of the optional Hybrid Cutting Head with Oxygen assist we can do that too. Our hybrid laser head with oxygen assist and RuiDa autofocus system makes cutting thin metal easy. The RuiDa autofocus system ensures that the Hydrid cutting head tracks the metal surface accurately over warps or bends, providing consistent cutting and gas pressure.

The 150W machine allows you to cut up to 18mm acrylic and 20mm mdf/ply in one pass and up to 1.5mm mild steel and 1mm stainless steel. The 300W and above allows you to cut up to 30mm acrylic and 25mm mdf/ply in one pass and up to 2.5mm mild steel and 2mm stainless steel. With the 300W you'll also be able to cut standard thinner materials (e.g. 3mm acrylic) at up to twice the speed of a standard 150W machine, reducing production time by up to 50%! The 500W and 620W versions are even faster.

If you need a camera system to cut preprinted material well we have got you covered. Each machine has our CCD 3 point camera system as an affordable optional extra.

The large bed size and the open design of the machine allows for easy loading of full size sheet for cutting. Our latest machine with ball rollers at the front of the machine provides a rolling surface for loading and un-loading sheets. Sheets can be loaded easily without scratching or damaging materials.

The precision Rack and Pinion drive provides higher accuracy for cutting and engraving when compared to standard belt drive and ball and screw systems. The higher acceleration and deceleration that this machine offers is particularly important for the super high speeds that the more powerful machines move at and also for metal cutting because it ensures consistency of cutting depth and smoother travel for a cleaner edge.

A top of the range S&A water chiller is included with all the machines. Extraction fan and small air pump are also included.

We supply SLW C02 Glass Laser tube system all our machines. We believe these are the best systems in the market and these tubes just like the machine is backed with a 12 month warranty. Most if not all our competitors offer 6 to 10 month warranty on their tubes. So if they don't trust the quality of their laser tubes, should you!!! You should also keep in mind that tubes 300W and above have a reasonably high replacement cost. Therefore the best quality SLW tubes will pay for themselves.

Our Rack and Pinion machines are also fitted with an automatic oiling system. You won't find this system on cheaper equipment and most of our more expensive competitors don't offer this solution either.

MACHINE FEATURES

Using high-speed laser optics which achieve high cutting speeds with minimal laser optic loss * II-V Focus Lens * Precision YASKAWA servo motor system MADE IN JAPAN * Aluminium Strip-Knife Table * large Chiller Unit for constant operating temperatures * CCD or overhead gantree camera system for cutting pre-printed product * Red Light Pointer * Special Laser Head/ Auto focus * High Speed/High-Precision Rack & Pinion Drive System which can achieve high transmission accuracy, up to 0.1mm, infinite length continuation and high transmission speeds, larger than 2m/s and maximum acceleration of 10,000mm/s with excellent precision and repeatability that ensures high quality cutting and smooth operation. With X- axis synchronous feeding for 24/7 operation and a service life of more than 10 years, the AXIS Bulltech RP2513-series Flat Bed machines represents stability and performance at an affordable price.

All this matched with the RD WORKS or Lightburn Software (other option available) laser cutting and engraving software gives you a powerful yet easy to use design and operating system. The RD WORKS and Lightburn software supports .PLT * .DST * .AI * GLD * .DXF * DWG formats. RDworks is compatible with PC and Lightburn is compatible with both PC and MAC OS computers. The Lightburn software package features easy, intuitive functionality. Click here to trial the Lightburn software

As an option we can supply you with fume extraction systems which are highly recommend for home, office and in fact anywhere where the smell of the laser cutting may be a problem.

Machines fitted with 300W laser tubes and above are not suitable for engraving.

SMPS Bulltech RP2513 from Peter Shephard on Vimeo.

Bulltech RP2513-300W - SD 480p from Peter Shephard on Vimeo.

Note: All products exclude GST where applicable at the current rate.

PLASQUIP has teamed up with a highly experienced Finance Consultant, Christos Kritikos from FINLEASE, to be able to offer our highly valued customers quick and efficient access to Equipment Finance for their purchase of Capital Plant and Equipment.

Ask Christos TODAY how to secure hassle-free finance for your equipment purchase – he can be contacted on his email below:

Landline: (02) 8404 2000

Mobile: 0448 005 890

Email: CKritikos@finlease.com.au

OR you can ask for Christos in the “comments” area in the FINLEASE Contact us page.

Delivery:

It is your obligation to enter the correct delivery address details at time of ordering. If you enter the wrong address, we are not obliged to re-send the order to the correct address at our expense. It is the responsibility of you the customer to inform us if an order does not arrive in a timely manner allowing for freight carriers normal delivery time frames to your address. All orders for product that is in stock is dispatched within two working days. If an order does not arrive please inform us. Once we learn an order has not arrived within the approximate delivery time frame, we will lodge enquiries with the freight provider to search for the order. We will not be held liable for any loss or damage resulting from late delivery, but will seek compensation on your behalf, for orders which do not arrive at all.

Without limiting the operation of any other Terms and Conditions herein, you agree that late delivery by a freight provider or Plasquip Sales does not constitute a failure of our agreement and does not entitle you to cancellation of an order.

Cancellations:

If you contact us before the order is shipped, we can refund you immediately. However, if the order has already been shipped, you will have to return the consignment to us at the below address. We (Plasquip Sales) reserve the right to cancel any order for any reason whatsoever. If you have already paid for an item ordered and we choose to cancel, your money will be refunded in full.

Refunds:

If you receive a product that you believe is significantly not as described, please contact us. After discussing the issue with us we will at our discretion refund your money after the return of the product/s. It will be your responsibility to return the item/s back to our address (at your cost, unless we are at, and have acknowledged, fault) in their original condition before a refund will be issued. Any item that we intentionally sell damaged, will be clearly marked as such.

Out of Stock:

Although we keep stock quantities of most products, on some occasions we run out of some products, which on average will delay an order, if this is the case, we will inform you via email of the estimated delivery time and give you the option to proceed with the order or cancel the order and receive a full refund.

Use our finance calculator from QPF Finance and Insurance to explore flexible payment options that work for you.