Featuring the intuitive ‘FCV’ (Formech Cycle View) user interface with a 7” touch-screen, the large sheet format 1250/1500 series is particularly well suited to automotive and aerospace R&D, sign and display companies and film & theatre set design.

Electric heater drive, pneumatic table and clamping provides effortless operation, whilst the vacuum tank system fitted as standard facilitates ultra-fast response for demanding applications and fast cycle times.

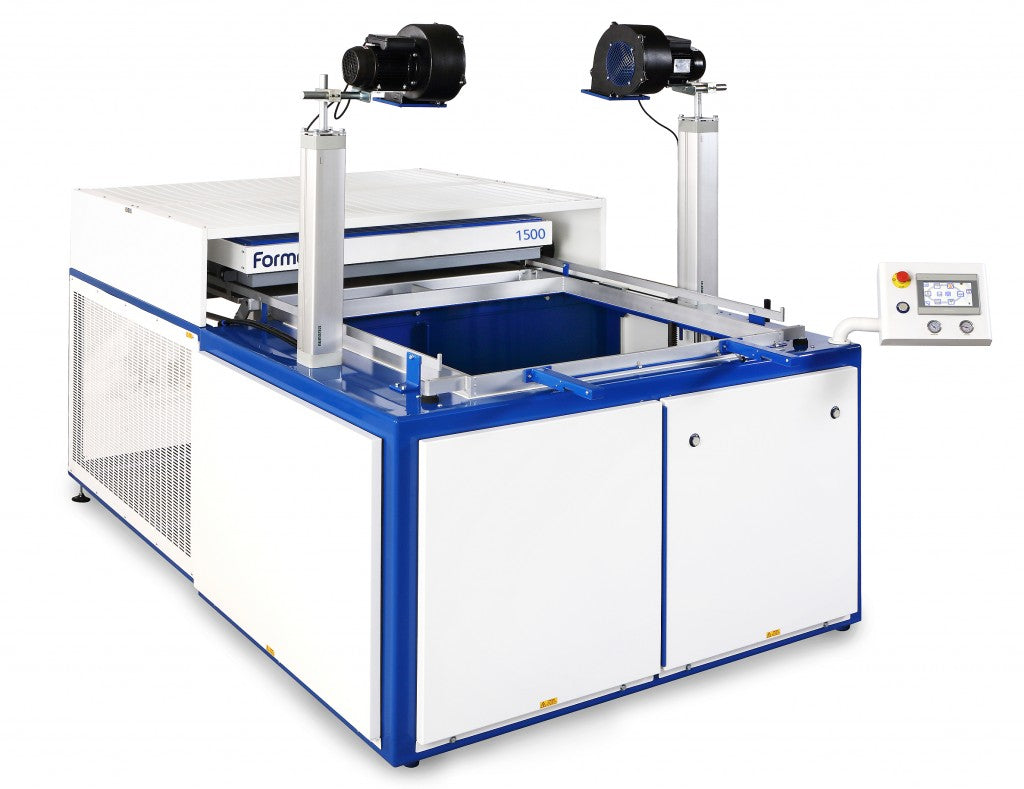

Designed to utilize sheet sizes of 1500 x 1000mm (1500) Formech’s 1500 series affords the operator a hands on approach versus more costly and fully guarded automatic machines.

7" Colour HMI/PLC featuring Formech Cycle View (FCV)

Wago control system with 7" colour touch screen, real time adjustments, 1% heater increment control, Formech Cycle View and 40 preset memories.

Quartz Heaters with Variable Standby

Quartz heaters have the benefit of a rapid response and high efficiency resulting in time and energy savings.

18 Independently Controllable Heating Zones

Eighteen heating zones and quartz heaters provide rapid heat response with a greater range of control to form challenging shapes and materials

Electric Heater Drive

Electrically powered heater travel for convenient operation. Controlled speed and braking prevents damage to elements.

Pneumatic Trigger Clamps

Pneumatically powered clamping system that provides powerful and effortless control.

Power Table

Lifts tool table quickly and precisely making effortless operation, even with heavy tools. Twin controls avoid accidental activation.

Table Height Adjust

Table height adjust shortens the tool table travel when using shallow tools and reduces cycle time.

Pre-Stretch

Pre-stretch enables the user to pump air into the heated sheet, creating a bubble to avoid thinning of material with deeper tools.

Auto-Level

Avoids material sag during the heating cycle and maintains an even distance between heater and sheet whilst providing the user with an audible indication the material is ready to form.

Vacuum Receiver Tank

A vacuum tank that provides instant stored vacuum, for high demanding materials and shortening cycle times.

Vacuum & Pressure Gauges

A visual indication of consistent vacuum and pressure being applied (pressure in Hg / bar).

Twin Cooling Fan System

Overhead gantry and twin 550W fans to cool formed material and shorten cycles times.

Oil filled rotary vane pump 21m3 / hr

Technical Specs

| Forming area (mm/inches) | 1460 x 960mm/ 57.5 x 37.8" |

| Sheet Size (mm/inches) | 1500 x 1000mm / 59 x 39.4" |

| Max depth of draw | 600mm / 23.5" |

| Max Material Thickness | 6mm / 0.25" |

| Heating Zones | 18 |

| Heater type | Quartz |

| Width | 2413mm / 95" |

| Height | 2200mm / 86.6" |

| Depth | 2876mm /113.2" |

| Weight | 950kg / 2094lbs |

| Single Phase Power Requirements | N/A |

| Europe - 3 Phase Power Requirements | 380-415v/40A |

| USA - 3 Phase Power Requirements | 208-220V/68A |

| Power Consumption | 25.0kW |

| Air Requirements | 80 PSI/5 bar |

Reducing Windows

Reduces forming area to utilize smaller sheets of material and minimize wastage. Standard or custom size.

Heating Pyrometer

Sensor to provide accurate sheet temperature feedback and send heaters back upon reaching target temperature (except on the 686 and 1372 where it gives a digital readout). Emergency air storage tank supplies cooling continuity on shut-down to protect pyrometer.

Cooling Bolster

A water cooled plate to directly cool and regulate aluminium tool temperature for consistent and faster cycle times.

Vacuum Flow Regulator

Precisely regulates vacuum flow rate when a greater level of control is required with demanding applications.

Multi User Pin Access Control

Spare parts kit

A consumable parts kit typically including seals, elements, filter, fuses, toggle clamps.

Featuring the intuitive ‘FCV’ (Formech Cycle View) user interface with a 7” touch-screen, the large sheet format 1250/1500 series is particularly well suited to automotive and aerospace R&D, sign and display companies and film & theatre set design.

Electric heater drive, pneumatic table and clamping provides effortless operation, whilst the vacuum tank system fitted as standard facilitates ultra-fast response for demanding applications and fast cycle times.

Designed to utilize sheet sizes of 1500 x 1000mm (1500) Formech’s 1500 series affords the operator a hands on approach versus more costly and fully guarded automatic machines.

7" Colour HMI/PLC featuring Formech Cycle View (FCV)

Wago control system with 7" colour touch screen, real time adjustments, 1% heater increment control, Formech Cycle View and 40 preset memories.

Quartz Heaters with Variable Standby

Quartz heaters have the benefit of a rapid response and high efficiency resulting in time and energy savings.

18 Independently Controllable Heating Zones

Eighteen heating zones and quartz heaters provide rapid heat response with a greater range of control to form challenging shapes and materials

Electric Heater Drive

Electrically powered heater travel for convenient operation. Controlled speed and braking prevents damage to elements.

Pneumatic Trigger Clamps

Pneumatically powered clamping system that provides powerful and effortless control.

Power Table

Lifts tool table quickly and precisely making effortless operation, even with heavy tools. Twin controls avoid accidental activation.

Table Height Adjust

Table height adjust shortens the tool table travel when using shallow tools and reduces cycle time.

Pre-Stretch

Pre-stretch enables the user to pump air into the heated sheet, creating a bubble to avoid thinning of material with deeper tools.

Auto-Level

Avoids material sag during the heating cycle and maintains an even distance between heater and sheet whilst providing the user with an audible indication the material is ready to form.

Vacuum Receiver Tank

A vacuum tank that provides instant stored vacuum, for high demanding materials and shortening cycle times.

Vacuum & Pressure Gauges

A visual indication of consistent vacuum and pressure being applied (pressure in Hg / bar).

Twin Cooling Fan System

Overhead gantry and twin 550W fans to cool formed material and shorten cycles times.

Oil filled rotary vane pump 21m3 / hr

Technical Specs

| Forming area (mm/inches) | 1460 x 960mm/ 57.5 x 37.8" |

| Sheet Size (mm/inches) | 1500 x 1000mm / 59 x 39.4" |

| Max depth of draw | 600mm / 23.5" |

| Max Material Thickness | 6mm / 0.25" |

| Heating Zones | 18 |

| Heater type | Quartz |

| Width | 2413mm / 95" |

| Height | 2200mm / 86.6" |

| Depth | 2876mm /113.2" |

| Weight | 950kg / 2094lbs |

| Single Phase Power Requirements | N/A |

| Europe - 3 Phase Power Requirements | 380-415v/40A |

| USA - 3 Phase Power Requirements | 208-220V/68A |

| Power Consumption | 25.0kW |

| Air Requirements | 80 PSI/5 bar |

Reducing Windows

Reduces forming area to utilize smaller sheets of material and minimize wastage. Standard or custom size.

Heating Pyrometer

Sensor to provide accurate sheet temperature feedback and send heaters back upon reaching target temperature (except on the 686 and 1372 where it gives a digital readout). Emergency air storage tank supplies cooling continuity on shut-down to protect pyrometer.

Cooling Bolster

A water cooled plate to directly cool and regulate aluminium tool temperature for consistent and faster cycle times.

Vacuum Flow Regulator

Precisely regulates vacuum flow rate when a greater level of control is required with demanding applications.

Multi User Pin Access Control

Spare parts kit

A consumable parts kit typically including seals, elements, filter, fuses, toggle clamps.

Note: All products exclude GST where applicable at the current rate.

PLASQUIP has teamed up with a highly experienced Finance Consultant, Christos Kritikos from FINLEASE, to be able to offer our highly valued customers quick and efficient access to Equipment Finance for their purchase of Capital Plant and Equipment.

Ask Christos TODAY how to secure hassle-free finance for your equipment purchase – he can be contacted on his email below:

Landline: (02) 8404 2000

Mobile: 0448 005 890

Email: CKritikos@finlease.com.au

OR you can ask for Christos in the “comments” area in the FINLEASE Contact us page.

Delivery:

It is your obligation to enter the correct delivery address details at time of ordering. If you enter the wrong address, we are not obliged to re-send the order to the correct address at our expense. It is the responsibility of you the customer to inform us if an order does not arrive in a timely manner allowing for freight carriers normal delivery time frames to your address. All orders for product that is in stock is dispatched within two working days. If an order does not arrive please inform us. Once we learn an order has not arrived within the approximate delivery time frame, we will lodge enquiries with the freight provider to search for the order. We will not be held liable for any loss or damage resulting from late delivery, but will seek compensation on your behalf, for orders which do not arrive at all.

Without limiting the operation of any other Terms and Conditions herein, you agree that late delivery by a freight provider or Plasquip Sales does not constitute a failure of our agreement and does not entitle you to cancellation of an order.

Cancellations:

If you contact us before the order is shipped, we can refund you immediately. However, if the order has already been shipped, you will have to return the consignment to us at the below address. We (Plasquip Sales) reserve the right to cancel any order for any reason whatsoever. If you have already paid for an item ordered and we choose to cancel, your money will be refunded in full.

Refunds:

If you receive a product that you believe is significantly not as described, please contact us. After discussing the issue with us we will at our discretion refund your money after the return of the product/s. It will be your responsibility to return the item/s back to our address (at your cost, unless we are at, and have acknowledged, fault) in their original condition before a refund will be issued. Any item that we intentionally sell damaged, will be clearly marked as such.

Out of Stock:

Although we keep stock quantities of most products, on some occasions we run out of some products, which on average will delay an order, if this is the case, we will inform you via email of the estimated delivery time and give you the option to proceed with the order or cancel the order and receive a full refund.

Use our finance calculator from QPF Finance and Insurance to explore flexible payment options that work for you.